Automated Part Indexing and Positioning

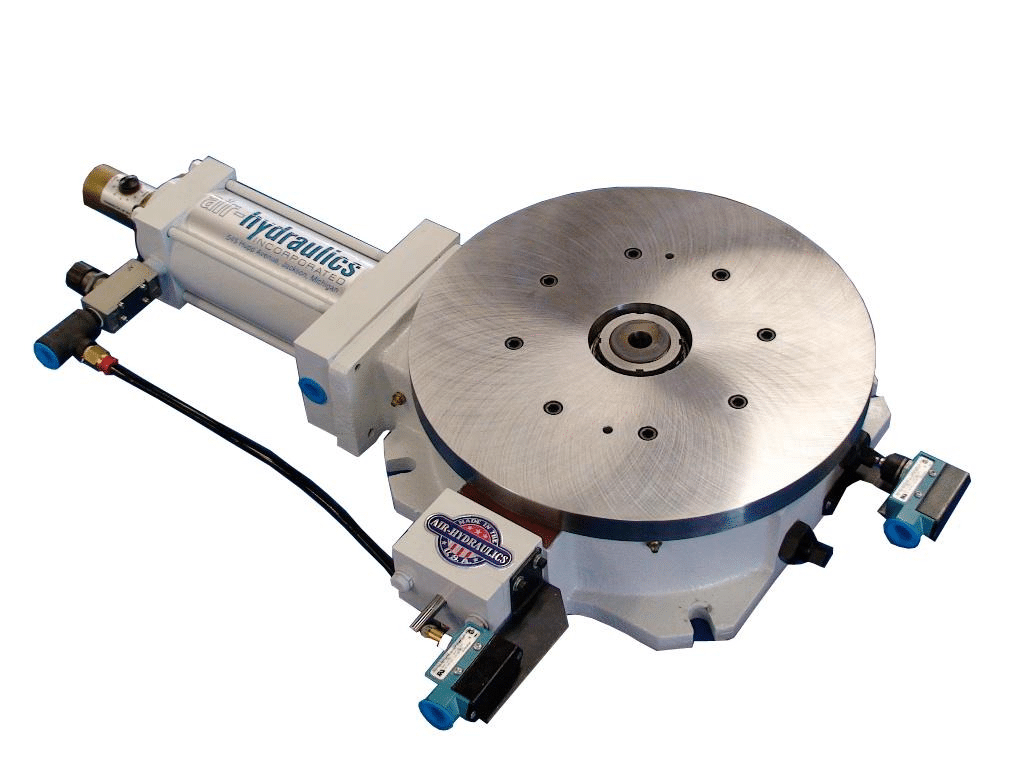

Pneumatic Rotary Index Tables

We manufacture 7” to 15” air-powered positioning tables for use in your next assembly or machining project. By using shop air, an indexing cylinder, and accurate locking mechanisms, we can ensure smooth and controlled motion without the use of electric motors or controllers, for simple and efficient, automated indexing and positioning. Compare models or request a quote today.

Extremely reliable, low maintenance, and accurate pneumatic rotary index tables for your assembly process with a low-profile, yet heavy duty design. Compare models to see which indexing table will work for your application, or request a quote based on your needs for our recommendation and pricing.

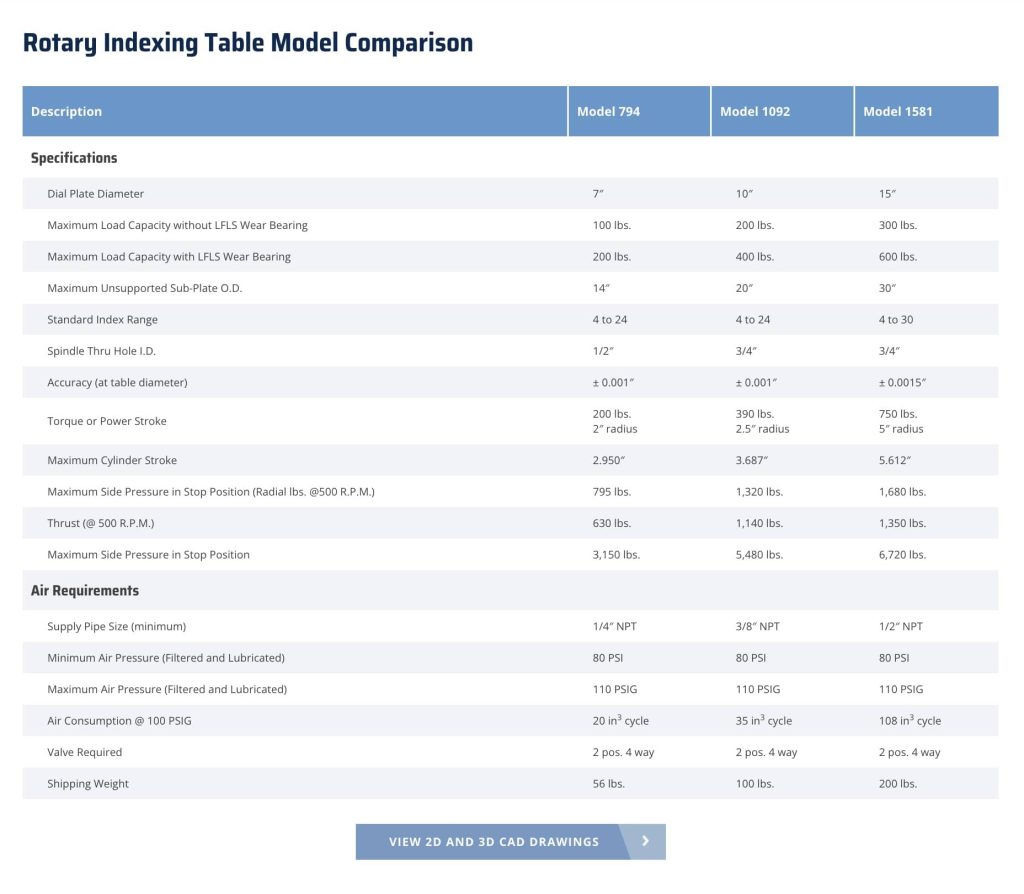

Compare Models

Download includes detailed specifications on the 7”, 10” and 15” models as well as links to 3-D and 2-D CAD drawings.

Standard Indexing Table Features

- Tapered Roller Bearing Construction

- Postive Index, Postive “Shot Pin” Locking

- +/- .001″ Accuracy at Table Top Diameter

- Two Electric Microswitches To Sense Indexing and Locking Positions

- Up to 24 Indexing Stations Available

- Clockwise Rotation

Available Options

- LFLS Wear Bearing (Low Friction Load Surface) – Reduces rotary friction and doubles load carrying capacity

- Shock Absorber (10″ and 15″ only) – Mechanical device mounted on blind end of index cylinder to absorb high shock loads (Clockwise rotation only)

- Sub plates – Aluminum or steel tooling plates, mounted or unmounted, with or without fixture mounting holes

- Pneumatic, Oil-tite or Explosion-proof limit switches (micro switches are standard)

- Power System (PS-E) which includes F-R-L, 120V Solenoid Operated 4/2 Directional Valve, Muffler, and Air Tubing. Note: Solenoid valve available in 24vDC, please consult factory.