Application

Swaging Press Applications

What is Swaging?

Swaging is a type of metal forming used to create or manipulate tubes, wires, pipes, cables, housings, and more. This process is often used to connect hollow metal parts, fix them into place, or change their shape according to specific applications. This process does not remove any materials, but rather reworks the metal. There are many different types of objects formed by swaging, and many different applications.

Tube Swaging by extrusion forces material through a die, manipulating the shape of the workpiece to make the diameter more narrow. This process is essential for manufacturing components across a variety of industries, from medical equipment to aerospace components to consumer appliances and more and requires a very large press that is able to apply a significant amount of force.

Rotary Swaging, also called radial swaging or radial forging, uses multiple dies to make a round workpiece smaller. Radial swaging may use wedges around the dies to manipulate the workpiece into a particular shape. This allows the workpiece to become narrower, and it can also create different fixtures, such as a hexagonal interior with a smooth exterior. To fix the pieces together, the process may be reversed to flare the workpiece and expand the diameter.

Metal Swaging Uses and Applications

Swaging is a highly versatile process with many different applications across a range of industries. Swaging is often used to make circuit boards for many different electronics, and can be an alternative to soldering. With the right amount of force, you can use a press for swaging heavy-duty metal cables, shaping pipes, attaching fittings, and much more. From delicate electronics to durable pipes and fittings for aeronautics and automotive parts, firearms, building materials, consumer products, etc – swaging and metal swaging presses are important machines for many different components across various industries.

Swaging Press Applications

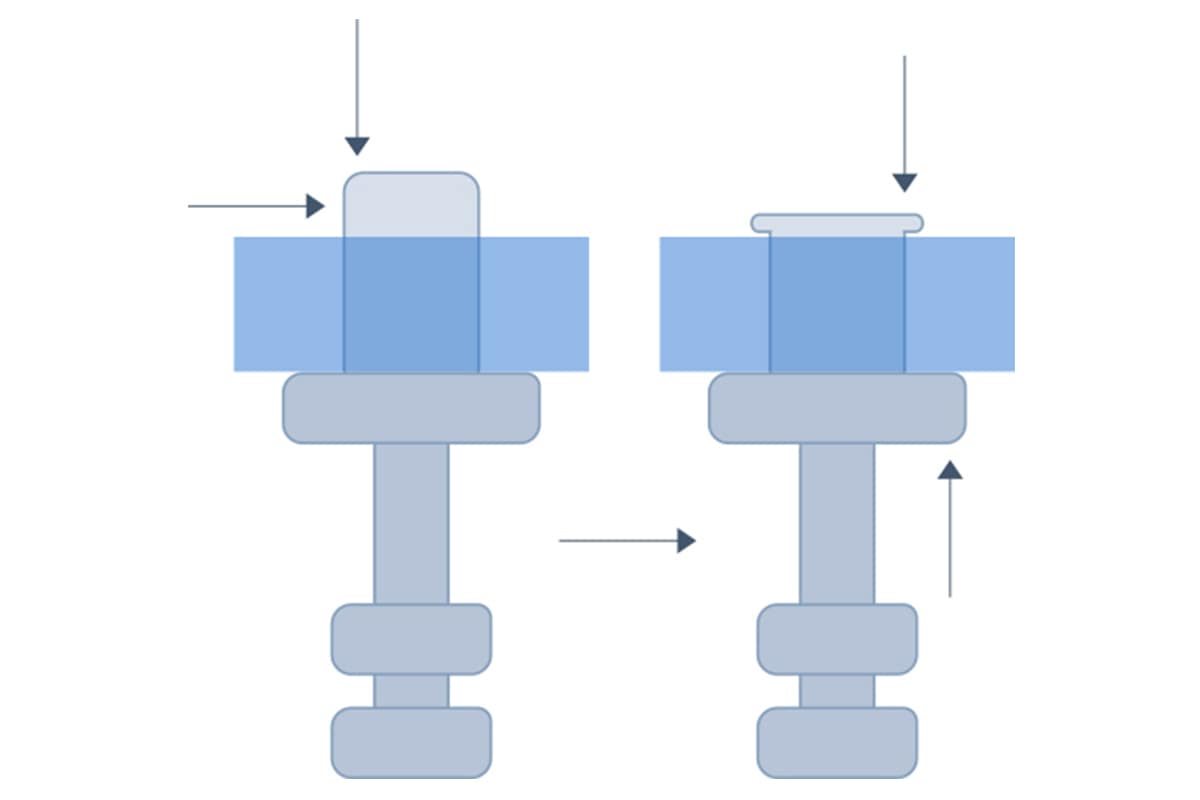

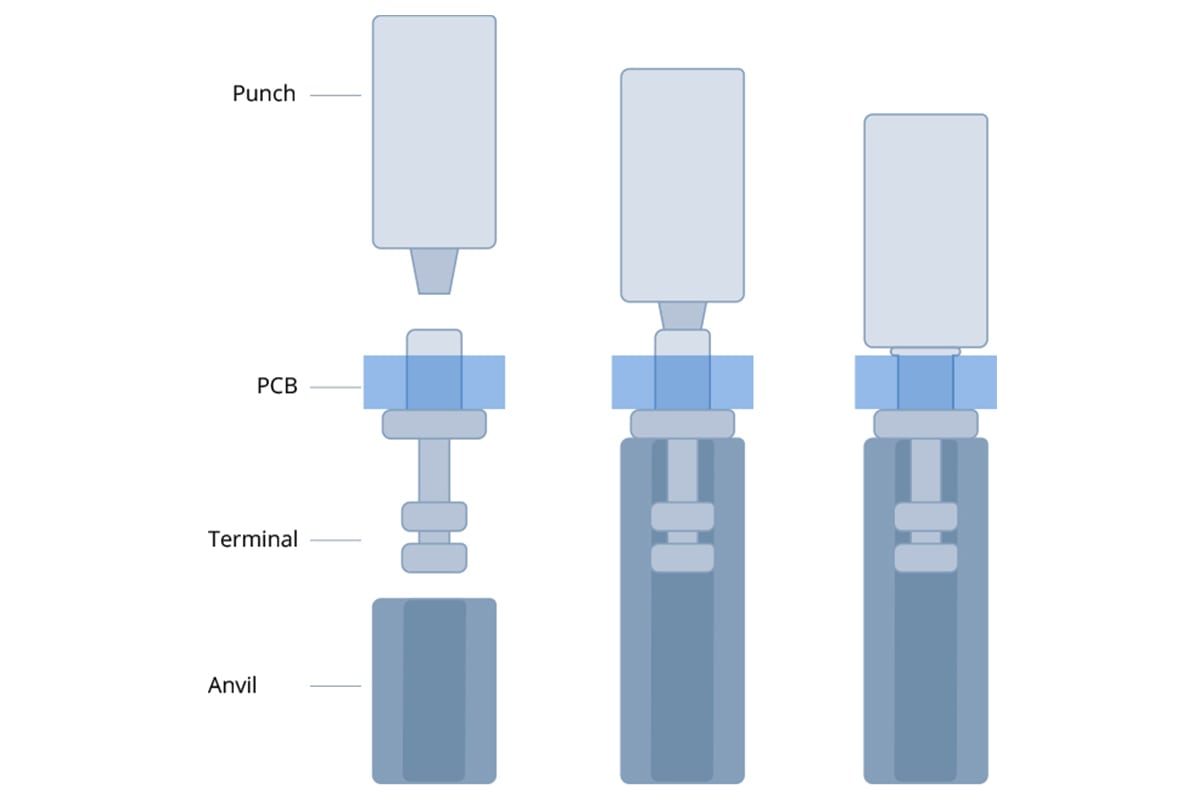

Swaging can be accomplished with a press, using the correct punch and die setup. In the swaging process below, an angled punch tooling rounds and flattens the hollow tube when pressed down into the receiving anvil, securing a connector to a printed circuit board (PCB). This is a common swaging press application.

Air Hydraulics Presses for Swaging:

- A-Series Adjustable Air Press

(1200-5000 lb) - AP-Series Black and Webster Air Press

(150-1900 lb) - C-Series Air Over Oil Press

(2.5-15 ton)

- AH-Series Hydropneumatic Press

(4-50 ton) - HP-Series Hydraulic Press

(20-50 ton) - SH-Series Compact Hydraulic Press

(2.5-15 ton)

There are many different tools that can be used for swaging with pneumatic, hydropneumatic, and hydraulic presses. Which type of press is ideal for the swaging job depends on the type of metal you’re working with, how you are manipulating the metal, and the size and shape of the object. This also depends on the type of swaging, such as radial swaging, roller swaging, pipe swaging, and more. If you’re not sure what type of press is best for your needs and applications, our experts can help. Contact us and we can tell you more about each press and help you find the right machine for your needs.

Interested in finding the best press for metal swaging?