Case Studies

Air-Hydraulics has created many customized machines for our customers needs. Our line of Hydraulic Presses, Air-Hydraulics Presses, and Air Presses can be easily modified to meet your form, fit, and control function requirements, or integrated into a full turnkey Press Automation System. Our design and application engineering will work with you to offer you, our customer, an affordable solution to your assembly and/or forming needs.

- All

- Air Presses

- Air-over-Oil Presses

- Force and Distance Monitoring

- Hydraulic Presses

- Impact Hammers

Case ID: 12495

Issue: Provide a full turnkey solution to accommodate and successfully assemble all the intended pump housing models, with the ability to communicate with the end-user manufacturing software system. Machine to also needed to be equipped with press guarding and safety light curtains.

Resolution: Model SIG-400 Air-Hydraulics Force & Distance Monitoring Press designed with a custom slide platen fixture and interchangeable fixtures to accommodate all the various size pump housings. The control system was designed and set-up to communicate with the customer’s internal manufacturing software system to follow and adjust parameters according to each assembly process. Equipped with full press barrier guards & safety light curtains.

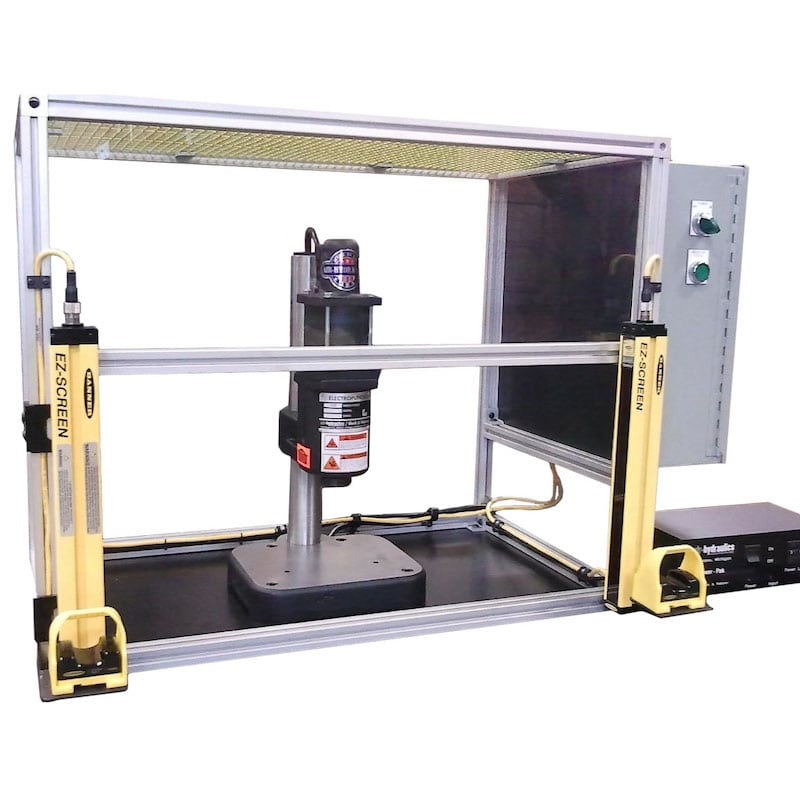

Case ID: 11108

Issue: Punch / stake valve body to hold the internal spool mechanism from coming apart. Machine to have the ability to cycle up to 30 cycles per minute and be guarded in a high production work environment

Resolution: A 4-Ton Model BS Electropunch (electric impact hammer) with enclosed barrier guarding and safety light curtains

Case ID: 9916

Issue: Apply and hold pressure on a 2-piece main antenna panel assembly for an extended period of time, while the adhesive between the two pieces cured

Resolution: Custom designed 1 ton, 4-post air press with movable middle platen, complete with two-hand actuated controls with pressure initiated clamping circuit and an adjustable time-out notification indicator

Case ID:

Issue: Application required a maximum of 6,000 lb. of force to press and seat the bearing into the housing. Machine needed to cycle automatically and also needed to be equipped with proper safety guarding.

Resolution: 5.5 Ton Model C-300 Air-Hydraulics Press with two-hand initiated auto cycle, pressure initiated automatic ram return, press barrier guarding, and light curtains

Case ID: 11500

Issue: Machine needed to be up-acting and produce at least 6,000 lb. of force to press roller bearings onto its mating drive shaft. Machine was to be installed in a new integrated assembly line at one of the customer’s facilities.

Resolution: Custom designed 5.5 ton up-acting air over oil press with roller conveyor to match those used in proposed assembly line. Addition of drive shaft carrying fixtures to easily slide the shaft along the conveyor, along with slide-on tooling rings for pressing roller bearings onto the drive shafts.

Case ID: 10418

Issue: The press needed to consistently generate up to 8 tons of force in a semi-cleanroom environment, protected from outside elements during the pressing process. It also needed the ability to be automatically cycled.

Resolution: Custom designed Model C-400 Air-Hydraulics Press with an enclosed interlock guarding, auto mode of operation, and an auxiliary air tank to accommodate any factory airline fluctuations.

Case ID: 11820

Issue: Design a machine to character stamp a number of different size gear shafts. Machine needed the ability to have an easy and quick changeover feature.

Resolution: Custom Design Model-C Electropunch with an Adjustable Fixture Using Angled Gear Racks

Case ID: 13008

Issue: Ability to consistently press a hinge shaft into the mating aluminum housing at the required depth. The process needed to be repeatable, so that the assembly was manufactured to its intended design. The customer also requested some additional safety features to accommodate their factory floor requirements.

Resolution: Air-Hydraulics Model 28-A Adjustable Air Press with Positive Downstop Adjustment, Pressure Initiated Auto Return, Pneumatic Dump Feature and Press Barrier Guarding

Case ID: 12181

Issue: Ability to control the pressing force in the first operation of the fastener assembly and then control pressing distance on the final operation of the fastener assembly.

Resolution: Outfit the press with a special Electric Dual Opto-Touch Control Package, Jog Control Circuit and Selectable Pressure/Distance Ram Return alongside a Custom Designed Guarding & Light Curtain Package

Case ID: 12680

Issue: Provide a more efficient solution for the installation of metal encased seals into light truck wheel hub assemblies

Resolution: A 2.5 ton air over oil press with an end of ram gas spring pressing tool and more

Case ID: 12084

Issue: Provide a more efficient solution to eject the filtration elements from their mold cavity

Resolution: A custom design 5.5 ton air over oil press

Case ID: 11987

Issue: To provide process monitoring and verify that each part assembly was pressed together

Resolution: 15 Ton AH-Series Air Over Oil Press outfit with Force & Distance Monitoring including Data Collection

Case ID: 12604

Issue: The customer had a safety concern with their existing press and wanted a press with a two-hand control safety device

Resolution: This press was outfitted with a 3-position “Jog” circuit, which allows the operator the ability to stop the ram at any position in the downstroke by removing their hands from the finger switches

Case ID: 12731

Issue: Automate processes to puncture sheet metal multiple times for each unique part

Resolution: The press was integrated with an adjustable digital cycle counter

Case ID: 12524

Issue: This press needed to be built and configured to perform 10 unique pressing operations

Resolution: The custom programmed Human Machine Interface (HMI) allows the operator to control each process digitally

Case ID: 12307

Issue: Updating a whole set of machinery to bring operations up to speed with current standards and regulations

Resolution: Detailed cleaning and testing of all 8 machines, rebuilding of cylinders, new paint jobs, and installation of all new and updated controls

Case ID: 12231

Issue: It was of extreme importance that these pins were inserted perfectly at each step

Resolution: A Cognex Insight Vision Sensor was installed and programmed for automated error detection to ensure accuracy of the pin insertion process

Case ID: 11225

Issue: Customer required a press with quality control monitoring within their allowed budget

Resolution: Air-Hydraulics provided an affordable press force monitoring package with three modes of operation

Let’s Work Together