Application

Metal Forming Press Applications

What is Metal Forming?

Also called plastic deformation, metal forming occurs by utilizing the moldable aspect, or plasticity, of certain metals and applying enough stress to permanently change the shape of the metal by either stretching, rolling, braking, punching, or pushing it through a separate object to form. Metal forming operations do not take substance away from or alter the material mass of the original sheet metal, block or billet and can be performed on a variety of metals such as steel, copper, aluminum and more.

Forming with Press Machinery

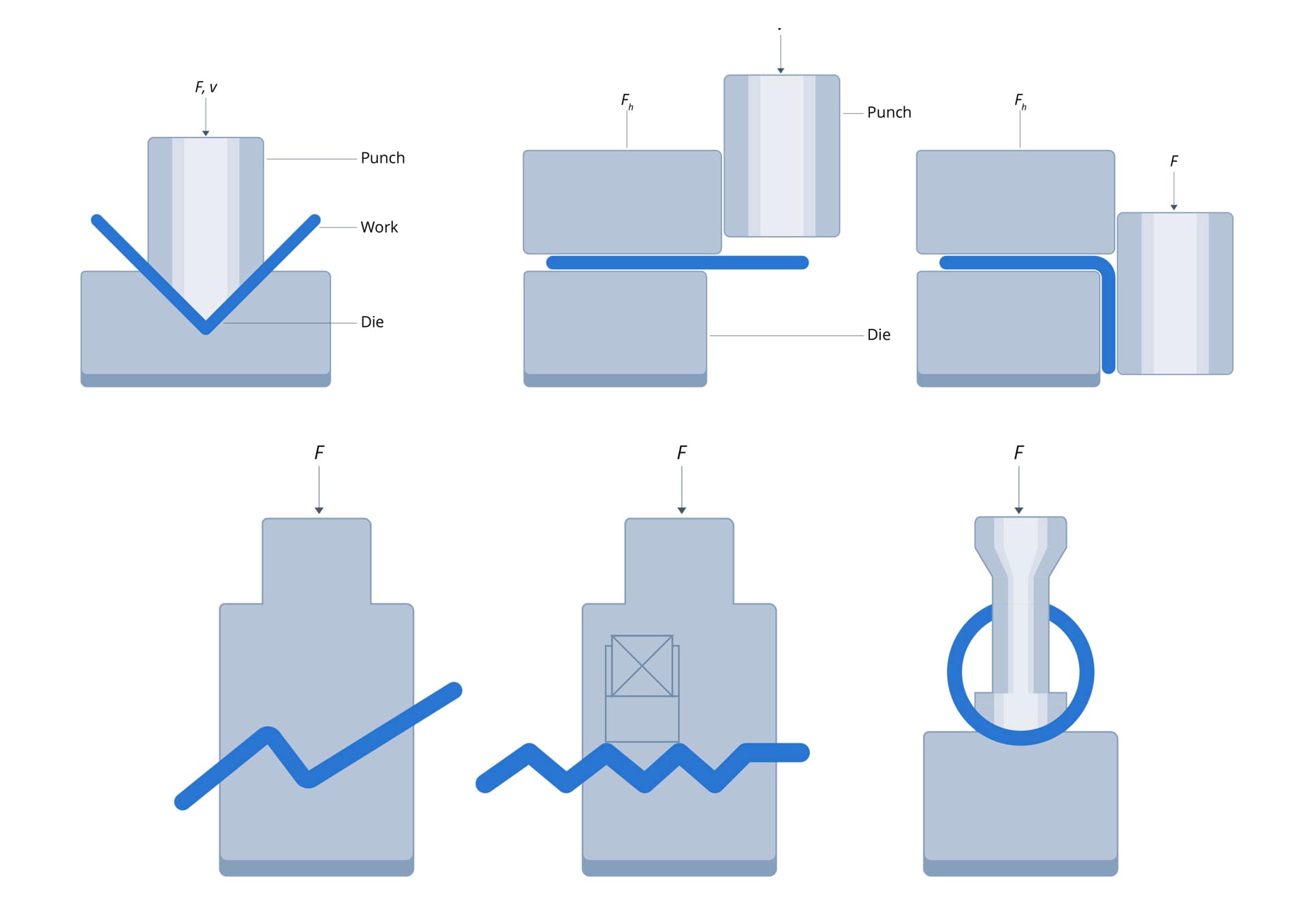

A press is used for forming sheet metal in various ways via different die setups between the ram and plate. Die forming does not refer to metal removal, but rather applying enough pressure or impact force to permanently bend the metal to the shape created between the two forms. This can create a fold or brake in the metal, or the material could be pressed into a particular shape and stretched to form. Take a look at some different ways press machinery can form metal:

Bending Presses

Shown to the right, there are many possibilities for bending metal to form with press machinery, depending on your punch and die setup. V-bending is achieved when the punch is shaped as an angle that fits into a die of the same form, and the metal is bent between the two objects. Angles can be as acute or obtuse as needed, and you can create a series of bends or use a rounded punch to achieve different custom forms.

Edge-bending involves compressing one side of the metal and then punching the opposite side over a straight axis to bend to a 90 degree angle.

Sheet bending does not change the thickness of the metal at any point.

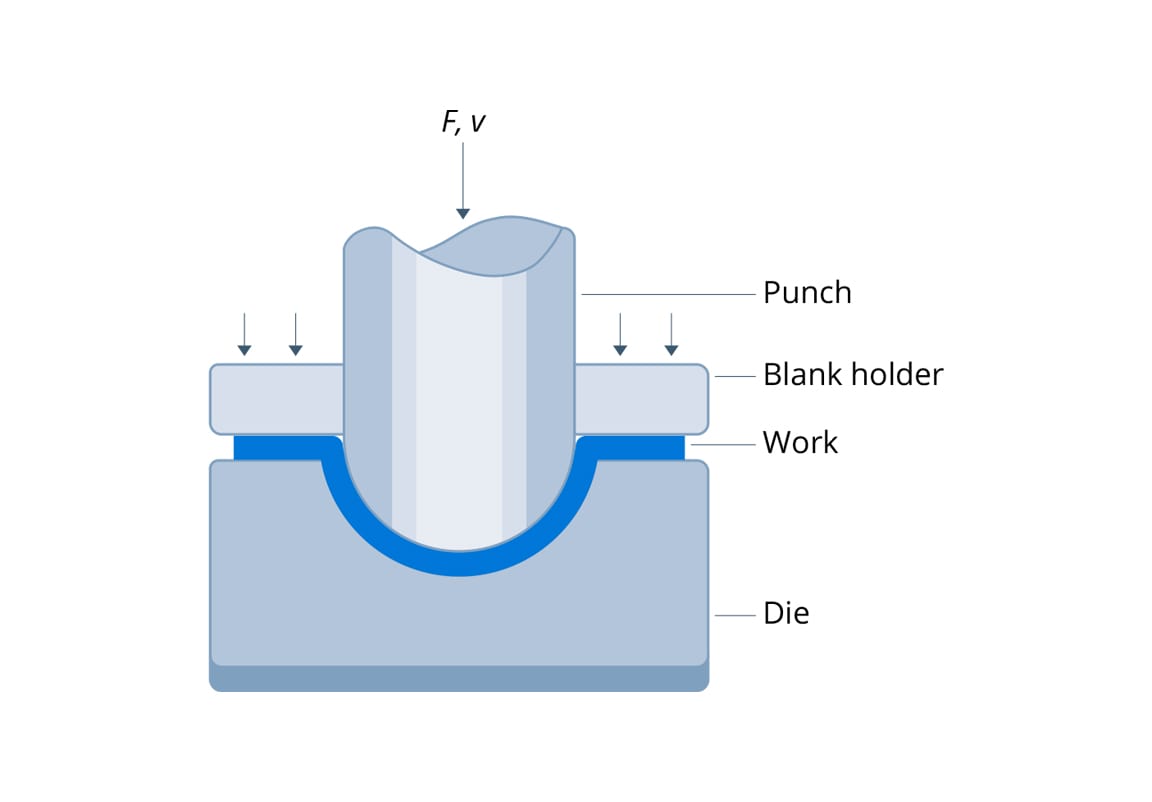

Deep Drawing / Cup Drawing

Deep drawing, or cup drawing, is performed with a similar punch and die operation, but the material is compressed on both sides of the die, and the punch stretches the material downward into a cupped shape.

This causes thinning of the metal at the walls of the cup, as the material must be stretched over a longer distance as the punch plunges downward.

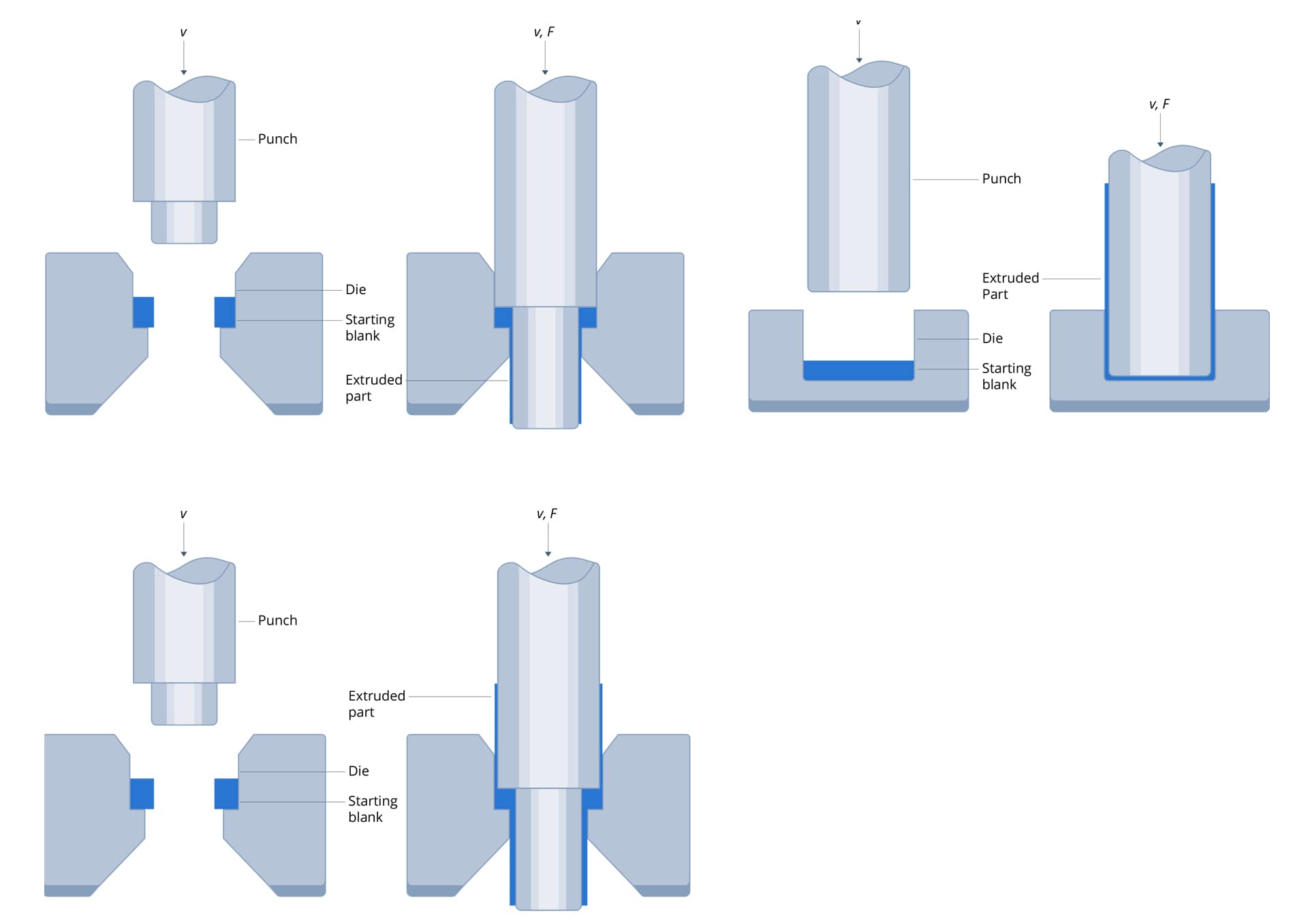

Impact Extrusion

Impact extrusion is applied with higher force and shorter strokes applied to a square or circular cross-section of metal, or billet, which is extruded by impact pressure through the die. This creates the ability to form more complex shapes within the fixed cross-sectional profile.

Direct, or forward extrusion / indirect, or backward extrusion and combined forward and backward extrusion, as shown in the diagrams, can all be produced with downward pressure of high impact force.

Metal Forming Uses

Metal forming is a useful application across many industries, such as automotive, aerospace engineering, appliance manufacturing, building and developing part manufacturing, packaging, etc. Any time a metal part needs to have a particular shape or fold without cutting material, metal forming is used to achieve the desired part specifications. Using automated press machinery for metal forming applications can increase efficiency, accuracy and overall productivity for operations over a wide range of industries.

Interested in finding the best press for your forming needs?