Application

Staking

Staking with Factory Presses

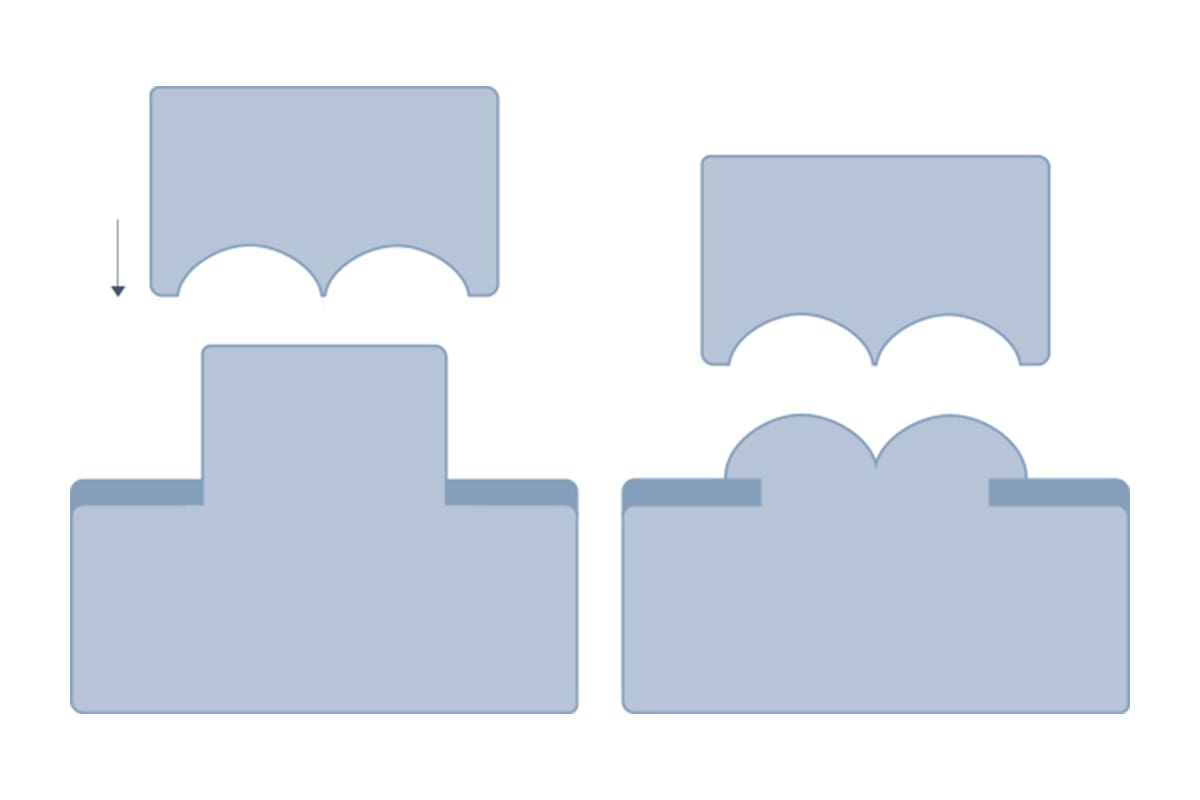

Staking is a fastening process producing secure, interference fits. This process deforms metal to join two metal pieces together. During the staking process, a protrusion in one piece meets a hole in another. The protrusion is deformed so it creates a high-friction fit between the two. This is an effective way to fix pieces together without the messy process of adhesive or welding. This process can also avoid additional fixing components, like pins or screws. With the right amount of force applied in the correct way, staking can join metal pieces tightly.

Staking for All Applications

Staking can be used for many different metals, and it’s also a common process for many types of plastics. This process is important when it comes to manufacturing and assembling many different automotive parts, belt pulleys, motors, bearings, and more. The right process can produce a tight fit that is flush with the metal piece, rounded, or flared. This process may be a critical part of the design and assembly phase, or it may be a decorative or aesthetic choice. Depending on the type of metal, application, and join you are working with, the amount of force required for your press will vary. To learn more about the different types of presses available for metal staking, contact us.

Types of Staking

There are many ways to deform metal pieces to create a tight join. The staking process is similar to swaging and flaring, with some important differences. Staking joins parts by pressing a protrusion in one piece against another flat piece. This might include cold press staking, thermal staking and in-die staking, among other processes. Staking is an important part of plastic molding, metal fabrication, assembly, and manufacturing for many different parts and equipment. The following processes are just two examples of staking processes that our factory presses can complete.

Press Staking

Staking processes manipulate protrusions to join pieces together by forcing an overlap with a shaped punch tooling. The top of the protruding piece, or boss, may be pressed into different shapes, including rounded, flat, flared, knurled, or hollow. This is helpful for joining differing metals that may corrode if they’re welded together or materials that cannot be welded, such as fixing plastic pieces together or a plastic piece to a metal part.

In-Die Staking

In-die staking is used to fix protruding parts to a stamped part. This can be used to fix contacts, pins, and similar pieces to stamped parts. This can help to speed up the assembly and manufacturing process for complex metal parts. This process must be precise, and it’s important to work with a press that is both quick and accurate.

Air Hydraulics Presses for Staking:

- AP-Series Black and Webster Air Press

(150-1900 lb) - AH-Series Hydropneumatic Press (4-50 ton)

- HP-Series Hydraulic Press

(20-50 ton)

- SH-Series Compact Hydraulic Press

(2.5-15 ton) - C-Series Air Over Oil Press

(2.5-15 ton) - Impact Hammers

(up to 20 tons of impact force)

Find the Right Press for Your Staking Process

Staking can speed up your manufacturing process and make your operation more efficient. However, it’s important to find a press with the right force range, size, and functionality. We can help you find the right press according to your materials, components, factory, and process. Contact us today to learn more about any of our presses and find the right machine for your staking job.

Interested in presses for staking?