AH-Series

4 Ton to 50 Ton Hydropneumatic Cylinder

The AH-Series Hydropneumatic Cylinder is an “all in one” self-contained air-over-oil cylinder package that produces hydraulic intensified force using factory supplied air. Excellent for assembly projects, machine integrators, or machine tool builders that don’t want to deal with costly, high voltage hydraulic power units, these cylinders come at a lower cost, are quieter during operation and require less maintenance than full hydraulics. Our AH-Series Hydropneumatic Cylinder also takes up less space and can be easily designed into your next assembly system projects, offering a range of output forces up to 50 tons.

This hydropneumatic intensifier is ideal when you want hydraulic intensified power without noisy motors, leaky hydraulic tanks or heat and energy issues that come with full hydraulic presses.

AH-Series Intensifier Information

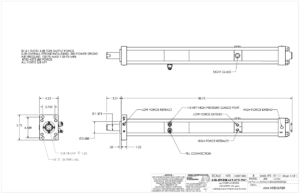

Contact manufacturer for the AH-Series manual, technical summary and details, or other information about this hydropneumatic cylinder.

AH-Series Intensifying Cylinder Model Comparison

| Description | AH4 | AH9 | AH15 | AH20 | AH30 |

|---|---|---|---|---|---|

| Specifications | |||||

| Force at 100 PSI Air (in lbs) | 8,750 | 18,500 | 31,400 | 38,700 | 65,100 |

| Power Ratio (No. x air line PSI= Approx. Force) | 87.5:1 | 18.5:1 | 314:1 | 387:1 | 651:1 |

| Max. Ram Stroke (including .500 power stroke) | 6″ | 6″ | 6″ | 6″ | 6″ |

| Cubic in. of Pressurized Air Per Full Stroke Cycle | .426 scfm | 1.079 scfm | 1.356 scfm | 1.568 scfm | 2.510 scfm |

| Air Cyl. Port Pipe Size (NPT) | 3/8 | 1/2 | 1/2 | 1/2 | 3/4 |

| Return Force at 100 PSI | 679 lb. | 942 lb. | 1648 lb. | 1648 lb. | 2335 lb. |

| Output Rod Diameter | 1.375″ | 2.000″ | 2.000″ | 2.000″ | 2.500″ |

| Net Weight | 70 lb. | 110 lb. | 150 lb. | 170 lb. | 225 lb. |

Standard Features & Options

Standard Features

- Air Operated – No Hydraulic Power Unit or Motor Needed

- Low Force / Fast Approach Stroke with a Self-Contained Hydraulic Intensified Power Stroke

- Flange Mounted

- Air Return – No Internal Springs

- Quiet Operation

- Compete with Pressure Sensing & Fill Ports

Available Options

- F-R-L Air Prep Package

- Speed / Flow Control Valve

- Hydraulic Pressure Sensor

- Alignment Couplers (for use with conventional die sets)

- Optional Anti-Rotation Feature

- Longer or Short Stroke Lengths

- Load Cell and/or Linear Transducers

- Custom Flange Mounting or Cylinder Rod Threads

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

AH-Series Hydropneumatic Cylinder Animation

Hydropneumatic Cylinder Operation:

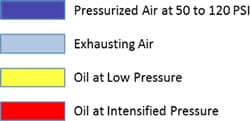

1 Actuating valve 1 pressurizes port 1, causing the float piston to move, transferring oil from the oil chamber onto the work piston at air pressure. The work rod extends at low pressure.

2 When the work is met, valve 2 is actuated, pressurizing port 2. This causes the booster piston and rod to extend, intensifying the pressure on the work piston, creating a high force.

3 – 3A Upon completion of the work, both valves are reversed, pressurizing ports 3 and 3A, retracting the cylinder to it’s start position