Electropunch

Electric Impact Hammers

These compact bench top electric impact hammers deliver instantaneous blows, which can be adjusted using either the Power Pak Controller or Impact Controller for impact forces ranging up to 8000 lb.

Applications: Staking, Riveting, Swaging, Crimping, Part Marking, and more.

These Electropunch electric impact hammers are powerhouses when it comes to metalworking and assembly applications. Providing rapid, repeated impacts, these tools enable faster completion of tasks compared to manual options, while also reducing operator fatigue, leading to sustained productivity over time. Robust, instantaneous impact force can be applied consistently to a wide range of tasks and materials, such as shaping, staking, or riveting metals, plastics or composites.

Electropunch Series Impact Hammer Information

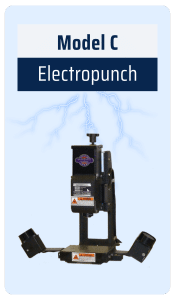

Model C

Our most powerful and heavy duty electropunch with impact forces ranging up to 15,000 lbs. Ideal for light taps to heavy impacts.

Model JS & FJS

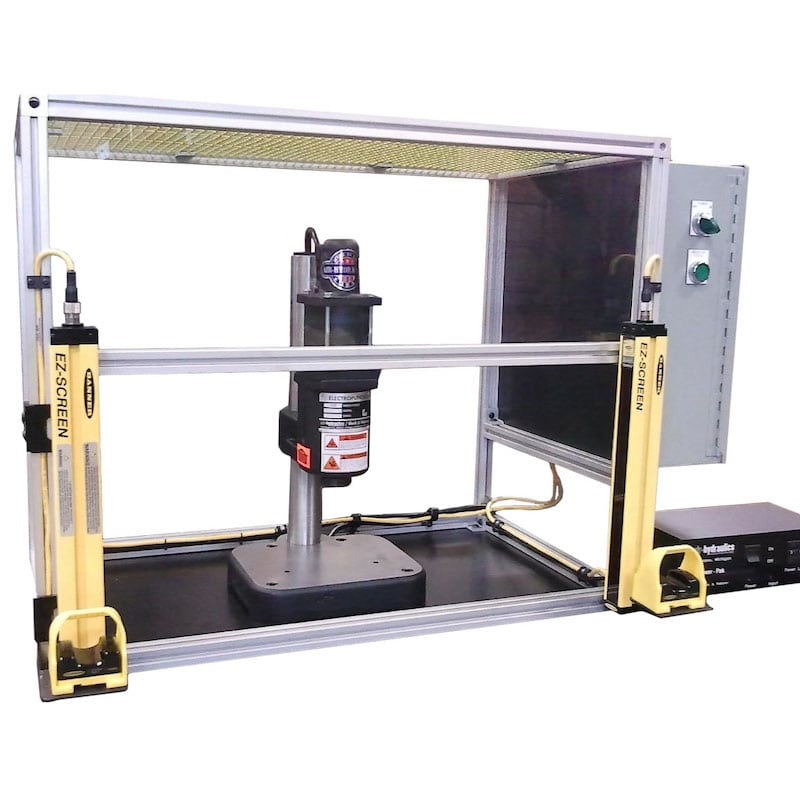

Popular for machine tool builders that are looking for an impact punch that is easily adaptable into an assembly system due to the flange style mounting design. Model FJS includes a frame, serving as a bench top press.

Model BS

Our most popular and flexible unit because of its column mounted design. This gives you the ability to easily adjust the working height for a variety of different job set-ups.

We also produce a Model SMS electric impact hammer, which consists of a hold-down mechanism to keep parts steady before an internal spindle fires to stake the parts together — contact us for information.

Standard Features & Options

Standard Features

- Screw Height (Daylight) Adjustment

- Heavy Duty Cast Frame

- All Electric Operation

- Non-Rotating Spindle

- 115V, Single Phase, 60 Cycle power

- Up to 15,000 lbs of adjustable impact force with Power Pak Controller

- 2.0” stroke with spring return

Available Options

- Electric Two Hand Non-Tie Down Actuators

- Electric Footswitch with Protectoswitch

- Bolster Plate Machined to Specs

- Custom Tooling Packages

- Custom Guarding Packages

- Impact head sold separately

Note: Power Pak Controller must be used with Model C Electropunch.

Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

*3D rendering of the product drawing and not a true image. Please see the drawing in the products dimensions section.

Standard Features

- Heavy Duty Cast Frame

- All Electric Operation

- Non-Rotating Spindle

- 115V, Single Phase, 60 Cycle power

- Up to 8,000 lbs of adjustable impact force with Power Pak Controller

- 1.75” stroke with spring return

Available Options

- Electric Two Hand Non-Tie Down Actuators

- Electric Footswitch with Protectoswitch

- Bolster Plate Machined to Specs

- Custom Tooling Packages

- Custom Guarding Packages

- Impact head sold separately

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

Standard Features

- Column mounted with adjustable daylight opening

- All Electric Operation

- Non-Rotating Spindle

- 115V, Single Phase, 60 Cycle power

- Up to 8,000 lbs of adjustable impact force with Power Pak Controller

- 1.75″ stroke with spring return

Available Options

- Screw Height Adjustment

- Electric Two Hand Non-Tie Down Actuators

- Electric Footswitch with Protectoswitch

- Bolster Plate Machined to Specs

- Custom Tooling Packages

- Custom Guarding Packages

- Impact head sold separately

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

*3D rendering of the product drawing and not a true image. Please see the drawing in the products dimensions section.

Standard Features

- Column mounted with adjustable daylight opening

- All Electric Operation

- Hold down mechanism to secure parts

- Foot treadle for hold down/impact initiation

- Non-Rotating Spindle

- 115V, Single Phase, 60 Cycle power

- Up to 8,000 lbs of adjustable impact force with Power Pak Controller

- 1.75” stroke with spring return

Available Options

- Screw Height Adjustment

- Bolster Plate Machined to Specs

- Custom Tooling Packages

- Custom Guarding Packages

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

Standard Features

- All Electric Operation

- Non-Rotating Spindle

- 115V, Single Phase, 60 Cycle power

- Up to 8,000 lbs of adjustable impact force with Power Pak Controller

- 1.75” stroke with spring return

- Flange mounting for positioning in any direction

Available Options

- Power Pak & Impact Controllers

- Cincinnati version available (please consult factory)

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

Note: Our objective is to offer you a solution to your assembly and forming needs. If our standard features or available options do not meet your application requirements, please consult our factory to see about us offering an affordable solution to meet your design needs.

Electropunch Model Comparison

| Description | Model C | Model FJS | Model BS | Model SMS | Model JS |

|---|---|---|---|---|---|

| Specifications | |||||

| Impact in Lbs. | 234 | 55 | 55 | 55 | 55 |

| Impact Force Lbs. Impact Controller Option | N/A | 3500 | 3500 | 3500 | 3500 |

| Impact Force Lbs. Power Pak Option | 15000 | 8000 | 8000 | 8000 | 8000 |

| Stroke | 2″ | 1.75″ | 1.75″ | 1.75″ | 1.75″ |

| Spindle to Base | Min 3.00″, Max 10.50″ | Min. 5.00″, Max. 5.00″ | Min. 0.00″, Max. 11.50″ | Min. 0.00″, Max 11.50″ | Min. N/A, Max. N/A |

| Throat Depth | 4.50″ | 4.00″ | 4.00″ | 4.00″ | N/A |

| Tool Weight | 7 Lbs. | 1 Lbs. | 1 Lbs. | 1 Lbs. | 1 Lbs. |

| Machine Weight | 90 Lbs. | 50 Lbs. | 50 Lbs. | 50 Lbs. | 20 Lbs. |

Custom Impact Hammer Modifications

- Light Curtains & Guarding Packages

- Custom Control Options

- Custom Tooling and Fixture Packages

- Selectable Modes of Operation

- And more.

Custom Electropunch Examples

The Air-Hydraulics Electropunch, Formerly from Black & Webster

This product was originally manufactured by Black & Webster, a company known for its robust and reliable industrial equipment. In 1990, Air-Hydraulics acquired the well-known Black & Webster Electropunch and AP-Series Air Press Lines. Since then, we have continued to manufacture and improve upon these legacy systems, ensuring they meet modern manufacturing demands.

Air-Hydraulics continues to produce the Black and Webster Electropunch, a powerful forming and punching solution widely used in automated production environments. Whether you’re replacing an aging Electropunch unit or integrating one into a new system, our team can assist with technical support, parts, and upgrades tailored to your application.

Impact Hammer Photos

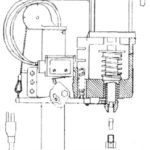

Electropunch Impact Hammer Manuals

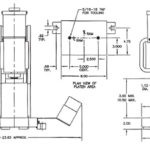

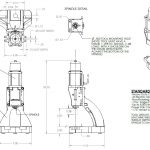

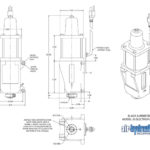

Electric Impact Hammer CAD Drawings

3-D viewing files do not require CAD software.

Interested in our Impact Hammers?