Impact hammers, otherwise known as power hammers, and industrial presses share many similarities, but there are also some key differences between the two machines. Both are used in shaping and forming metal components and workpieces, and both machines use large amounts of force to accomplish this. However, though these processes and machines look similar, the differences are important. Let’s compare impact hammers vs industrial presses, and take a look at the similarities, differences, and ideal applications of each.

Impact Hammer vs Industrial Press

First, let’s take a look at what a power hammer is, and what an industrial press is. Understanding the basics of each can help determine when to use an impact hammer vs an industrial press, and why.

What is an Impact Hammer?

An impact hammer, or power hammer, is a cold-forging machine that uses instantaneous and/or repeated striking force to shape a metal workpiece. The impact hammer consists of a frame, anvil, ram, and hammer head or die. The impact hammer may use an electrical, mechanical, pneumatic, hydraulic, or even steam power source to move the ram and hammer head onto the workpiece. Early versions of the impact hammer, used around the late 1800’s, simply used gravity to bring the hammer head down on the workpiece.

What is an Industrial Press?

An industrial press is also a cold-forging machine that uses force to shape a metal workpiece, except an industrial press generally uses slower, continuous force that pushes the workpiece into a desired shape, instead of repeatedly striking it. There are many different types of factory or industrial presses, also called machine presses or forming presses, including electric, manual, pneumatic, hydraulic, and hydropneumatic presses. The history of industrial presses dates back even farther than that of impact hammers, with some of the first presses being used in the 1500’s to make coins.

Differences Between Impact Hammers and Industrial Presses

Though impact hammers and industrial presses look similar and are often used in similar settings, there are some distinct and important differences between them.

Outside vs Inside Metal Working

The first and perhaps the most important difference between impact hammers and industrial presses is how they shape metal. A press exerts even, consistent force on the object over a longer period of time, which allows it to shape the metal to its core. The press works from the “inside out,” and can manipulate the shape more dramatically. By contrast, an impact hammer works repeatedly on the exterior surface of the object, shaping it from the “outside in,” and generally doesn’t have as much effect on the core of the workpiece. This distinction may seem somewhat arbitrary, but it has more serious implications depending on what you are trying to accomplish and how you want to do it.

Instantaneous vs. Progressive Strikes

The impact hammer delivers quick, instantaneous strikes with a consistent stroke. The force is applied immediately and dissipated shortly after, offering precise and repeatable impact pressure up to the tool’s full capacity. In contrast, industrial presses often build force gradually—starting with minimal pressure and ramping up to peak force only upon contact with the workpiece.

Precision vs Speed

In general, factory presses offer more precision and control than hammer presses. The ability to determine press force, monitor the operation with the right tools, and pinpoint the perfect power stroke allows the press to perform tasks with more accuracy. The impact hammer brings speed and force, but can be more difficult to control in more exacting applications.

Versatility

The factory press is also able to accomplish a wider range of applications than the impact hammer. Since the impact hammer is limited to repeated striking action, it generally has more limitations than the industrial press, which applies steady force. If you are looking for a dedicated machine for a single job, an impact hammer might be ideal. However, if you are performing several stamping, bending, bearing insertion, or other jobs, you’ll need a press. We’ll discuss applications and when to use an impact hammer vs industrial press later in the post.

Noise

You probably won’t be surprised to learn that the repetitive striking action of the impact hammer is generally louder than a comparable factory press. Though both machines can be loud and hearing protection is always recommended, it’s extremely important when working around an impact hammer. Pneumatic and hydropneumatic presses are generally quieter compared to impact hammers and hydraulic presses.

Features and Upgrades

Industrial presses can also be equipped with additional features and upgrades that can amplify their force, monitor their activity, detect issues, and improve precision. impact hammers are more limited in their capabilities and technological improvements. A hi/lo hydropneumatic cylinder, for example, can amplify the press force. Press force monitoring technology can improve quality control, reduce defects, and optimize performance. Rotary indexing allows the press to accomplish more complex jobs in quick succession. These, and many other features, generally aren’t available to impact hammers.

When to Use An Impact Hammer vs Industrial Press

Both an impact hammer and an industrial press have their places in manufacturing, forging, and metalworking in general. In many situations, these machines can be found side-by-side, performing different jobs which are both important in the manufacturing process.

When to Use an Impact Hammer

The fast, powerful nature of an impact hammer makes it well-suited for jobs that require more speed and intensity than refinement. This includes many forging tasks which shape metal workpieces into basic forms, as well as assembly tasks. Since impact hammers work effectively on the exterior of a workpiece, they are useful for some metal shaping tasks, such as producing length, curves, or angles. Impact hammers can be ideal for certain assembly applications as well, such as stamping applications like character stamping or marking, as well as many staking applications. Some impact hammers are commonly used in heavy equipment applications, such as shipbuilding or mining, while others are used in home-forge settings for bladesmithing and hobby forging.

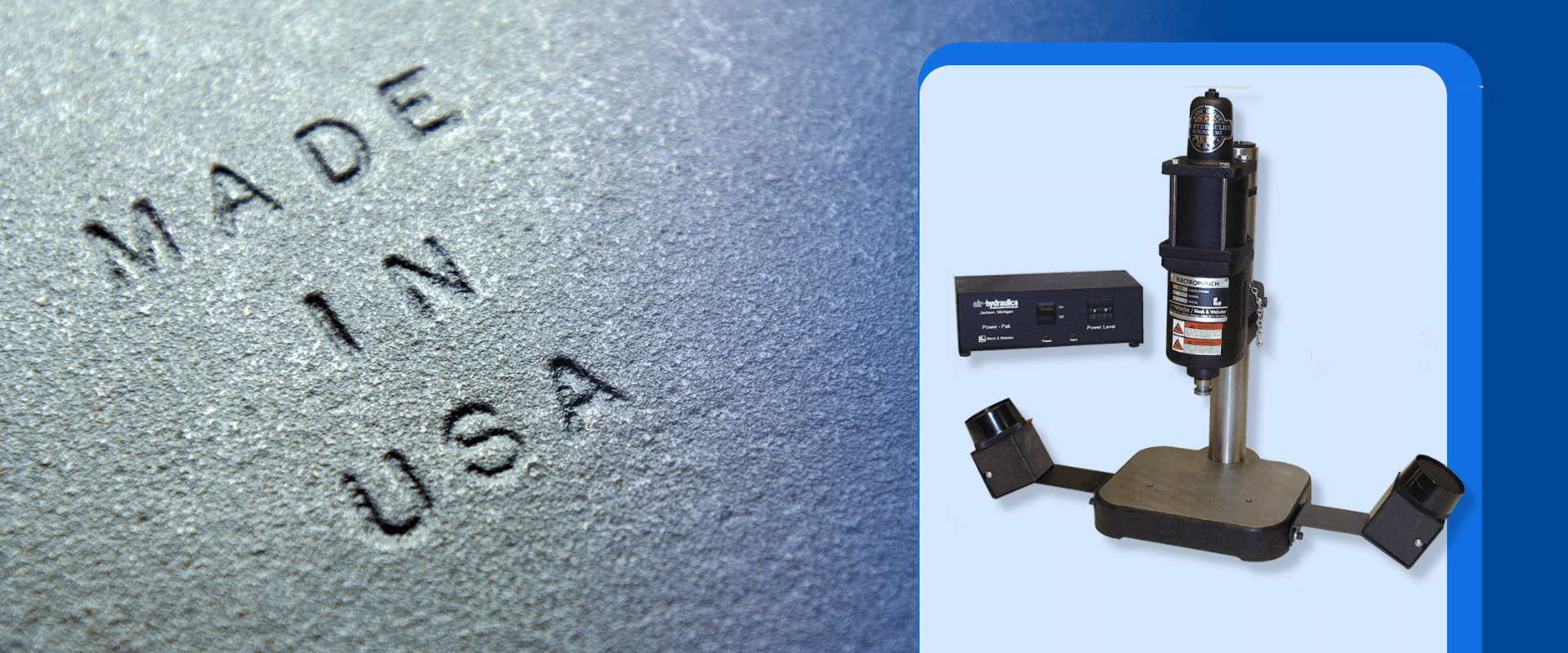

Air Hydraulics Inc. produces both pneumatically powered and electric impact hammers with models that deliver from 3,500 lb. to 20 tons of force.

Black and Webster Electropunch

Electric impact hammers delivering 3,500-15,000 lb. (7.5 Tons) Impact Force

Z-Series Pneumatic Impact Hammer

Air powered impact hammers that deliver from 6 to 20 tons of repeatable force

When to Use an Industrial Press

The wider array of applications, increased precision, and more careful nature of a factory press makes it better suited to many assembly applications, such as bushing and bearing insertion, pin or stud insertion, staking, and many other joining applications. Metal forming jobs with more complex shapes, such as deep drawing or impact extrusion, are also generally suited for presses. Other jobs that require more precision and which require altering the core of the material, such as heavier stamping, shearing and punching applications, are also ideal for a press. Finally, performing a series of tasks in quick succession to speed up manufacturing and assembly may be ideal for a rotary table enabled press, while high-precision jobs are ideal for a servo press. Just like an impact hammer, the range of presses is vast, with industrial presses used in high-volume production settings for aircraft or automotive components, and others used in home garages or small machine shops.

When to use an impact hammer and when to use an industrial press depends on your goals and applications. If you have questions about factory presses, we can help. Contact us today to get your questions answered.