Choosing the right type of press can significantly impact productivity and quality at your factory. Let’s take a look at the details of hydraulic presses for manufacturing and assembly, as well as some potential alternatives to hydraulic presses.

Your Press Process

There are many different factory presses to choose from, and finding the right press for your needs means matching the functionality and design of the press to the needs of your process. It’s important to assess your process first, so you know what to look for in a press, and then assess the different options available, so you can find the right fit.

As you assess your process, look for the following:

- Force: how much force does your process need? A few shortcuts can help you calculate force, which can help you hone in on the right-sized press.

- Speed: how fast do you need your press to operate? Consider the surrounding processes and your production needs.

- Job type: will your press be performing one or two jobs repetitively, or will you need to make adjustments to perform a variety of different tasks?

- Dimensions: consider the dimensions of your part or workpiece, as well as the space available in your shop. This can help you determine the stroke length needed, and the possible footprint of the press.

Hydraulic Presses for Manufacturing or Assembly

The following are a few of the most common presses used in manufacturing and assembly operations. We’ve selected these press types because of their versatility, functionality, stability, and power, which makes them ideal for a variety of different manufacturing and assembly tasks.

C-Frame Hydraulic Press

C-Frame Hydraulic Press

The C-frame hydraulic press is a versatile choice for manufacturing and assembly. Its open-front design allows easy access to the work area for easier die changing or adjustments and also for material loading, making it suitable for a variety of tasks such as bending, stamping, and forming. Since these presses are often smaller than 2 or 4-post presses by design, they are great choices when you’re dealing with limited floor space but still need the power of full hydraulic force. These presses are typically lower in cost compared to 2 and 4-post hydraulic presses as well.

Hydropneumatic presses are also available with a C-frame design. Air-over-oil presses can provide between 2.5 and 50 tons of force, allowing these models to accomplish many of the same jobs as hydraulic presses.

2 or 4 Post Hydraulic Press

For heavy-duty applications, 2 or 4 post hydraulic presses provide stability and strength. The vertical posts on each side of the working area can either be structural, or have a guided platen that moves along the posts for perpendicularity. In either case the hydraulic cylinder or cylinders are typically mounted at the top of these posts.

With non-guided 2- or 4 – post hydraulic presses, the structural configuration simply offers more room for larger pieces of working material. Guided systems provide an even surface area of pressure, exerting force horizontally along the surface area of the guided platen, ensuring perpendicularity for tasks that require a consistent and uniform application of force. These configurations may be required for punching several dies from a sheet of metal, foam or plastic, or for other applications like metal forming and pressing over a large surface area.

Alternatives to Hydraulic Presses

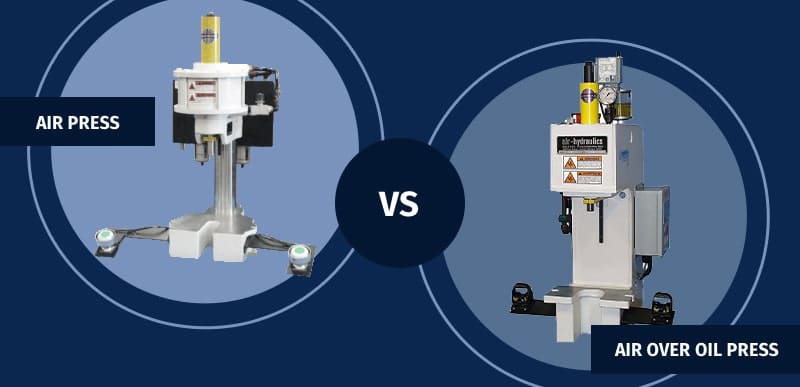

The following presses are not full hydraulic presses, but they fit the bill for jobs and applications that require hydraulic power and often come with higher efficiency and lower cost and maintenance, so they are worth mentioning in the same vein. These are hydropneumatic presses, the first of which is something uniquely designed to function just like hydraulic, with a higher return on ROI.

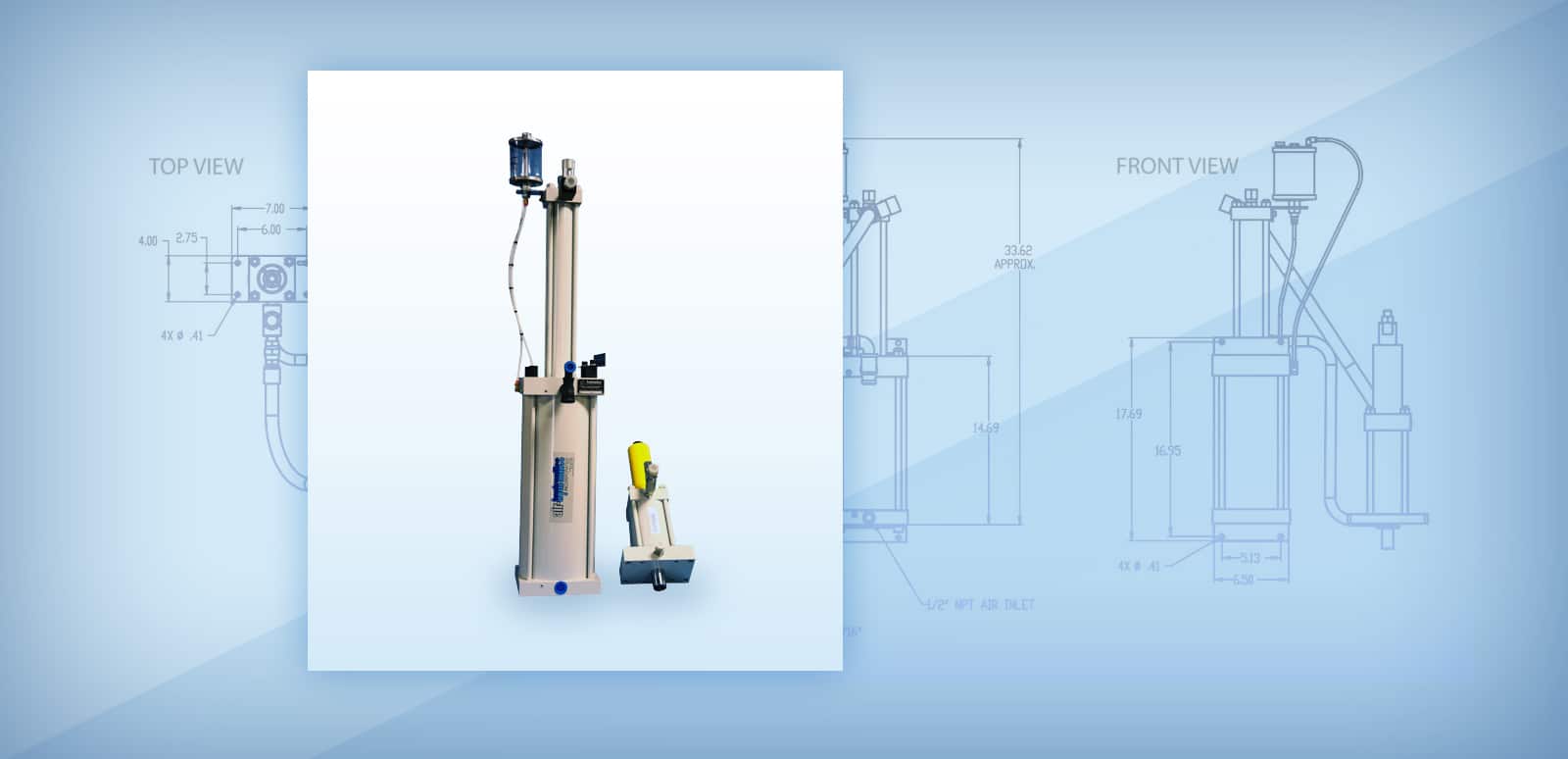

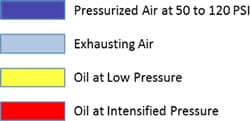

Rapid Advance Low-Force Hydraulic Intensified Air-Over-Oil Press

A hydropneumatic press is a great alternative to a purely hydraulic press for manufacturing and assembly. The Air Hydraulics line of AH-Series Hydropneumatic Presses provide a range of 4 to 50 tons of force. Since this model combines pneumatic and hydraulic forces, it works faster than a purely hydraulic press, and also requires less maintenance and initial investment. This model’s rapid, low-force approach stroke uses a hydraulic-intensified half-inch power stroke, providing a strong finish to a steady procedure, and also provides a low-cost, energy-efficient alternative to a single or 3-phase high voltage hydraulic power unit.

A hydropneumatic press is a great alternative to a purely hydraulic press for manufacturing and assembly. The Air Hydraulics line of AH-Series Hydropneumatic Presses provide a range of 4 to 50 tons of force. Since this model combines pneumatic and hydraulic forces, it works faster than a purely hydraulic press, and also requires less maintenance and initial investment. This model’s rapid, low-force approach stroke uses a hydraulic-intensified half-inch power stroke, providing a strong finish to a steady procedure, and also provides a low-cost, energy-efficient alternative to a single or 3-phase high voltage hydraulic power unit.

Full Powerstroke Air-Over-Oil Presses

While most hydropneumatic presses deliver intensified power within a half-inch of the cylinder stroke, air-over-oil presses designed with full power strokes like our unique C-Series Air Hydraulics Presses, can be the perfect alternatives to medium force hydraulic presses.

These presses combine the advantages of hydraulic and pneumatic systems, offering a full power stroke like their hydraulic counterparts, but using compressed air for the return stroke, providing efficiency and speed. The full powerstroke air-over-oil model press provides between 2.5 and 15 tons of force, with pressure maintained throughout the entire stroke. This type of press is ideal for bushing or bearing insertion, press fit, stud insertion, and many other manufacturing and assembly tasks. These presses provide the force of a hydraulic press, with reduced maintenance demands, increased speed, quieter operation, no high-voltage power requirements and a lower upfront investment cost.

View our Air Hydraulic C-Series Presses ›

Choosing the right press for manufacturing and assembly involves a careful consideration of force, speed, and control. Hydraulic presses, along with their alternatives, offer a spectrum of options. By understanding the nuances of each type, manufacturers can make informed decisions that contribute to the efficiency and success of their operations. If you’re wondering about which press is ideal for your manufacturing or assembly needs, contact us. We can help you find the right design, force, and features for your application.

Get a quote on the perfect press for your job or project

Provide a few details on your application requirements and any specific or custom features you’re looking for and we’ll get you a quote for the best press for the job.

Alternatives to Hydraulic Presses

The following presses are not full hydraulic presses, but they fit the bill for jobs and applications that require hydraulic power and often come with higher efficiency and lower cost and maintenance, so they are worth mentioning in the same vein. These are hydropneumatic presses, the first of which is something uniquely designed to function just like hydraulic, with a higher return on ROI.

Rapid Advance Low-Force Hydraulic Intensified Air-Over-Oil Press

Full Powerstroke Air-Over-Oil Presses

While most hydropneumatic presses deliver intensified power within a half-inch of the cylinder stroke, air-over-oil presses designed with full power strokes like our unique C-Series Air Hydraulics Presses, can be the perfect alternatives to medium force hydraulic presses.

These presses combine the advantages of hydraulic and pneumatic systems, offering a full power stroke like their hydraulic counterparts, but using compressed air for the return stroke, providing efficiency and speed. The full powerstroke air-over-oil model press provides between 2.5 and 15 tons of force, with pressure maintained throughout the entire stroke. This type of press is ideal for bushing or bearing insertion, press fit, stud insertion, and many other manufacturing and assembly tasks. These presses provide the force of a hydraulic press, with reduced maintenance demands, increased speed, quieter operation, no high-voltage power requirements and a lower upfront investment cost.

View our Air Hydraulic C-Series Presses ›

Choosing the right press for manufacturing and assembly involves a careful consideration of force, speed, and control. Hydraulic presses, along with their alternatives, offer a spectrum of options. By understanding the nuances of each type, manufacturers can make informed decisions that contribute to the efficiency and success of their operations. If you’re wondering about which press is ideal for your manufacturing or assembly needs, contact us. We can help you find the right design, force, and features for your application.

C-Frame Hydraulic Press

C-Frame Hydraulic Press