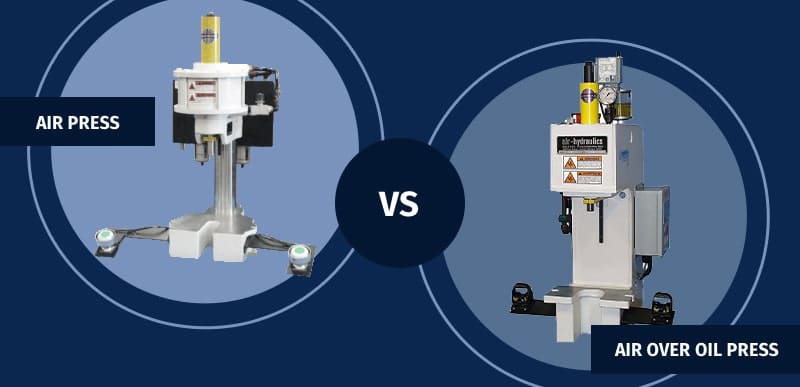

Finding the right press for your needs and applications can be difficult. There are many different options and configurations to choose from. Let’s take a look at the differences between an arbor press vs air press, and the situations that might be ideal for each.

Arbor Press vs Air Press: Functionality

Let’s start with the basics of an arbor press vs air press. What is an arbor press? What is an air press? How does the functionality of each one compare?

What is an Arbor Press?

An arbor press is a manual press that uses gears to multiply the force applied. Though arbor presses can apply up to 2 tons of force, they are often used for smaller jobs, such as staking and riveting. These types of presses generally fit on a workbench, and they’re relatively simple and easy to use.

What is an Air Press?

An air press, also called a pneumatic press, uses compressed air to drive the force behind the press. Manipulating the air pressure can change the force. Air presses can exert up to 5,000 pounds (2.5 tons), which can accommodate a wide variety of different press applications. These presses generally have more advanced features than manual options, but with a much smaller footprint compared to hydraulic presses.

View Air Hydraulics Inc Air Presses, built for production ›

Arbor Press vs Air Press: Advantages and Disadvantages

Arbor Press

The simple and straight-forward design of arbor presses offer a number of advantages, as well as some disadvantages. Understanding each of these can help you choose the right press for the right situation.

Advantage: Small Footprint

If your work area has limited space, an arbor press’s compact design can fit into tight spaces. Arbor presses are designed to sit on workbenches, so they don’t need dedicated floor space.

Advantage: Simple Operation

Though all presses require care and caution to operate safely, arbor presses are designed to be simple. They don’t require a lot of training to operate, and it’s possible to get started quickly.

Advantage: Affordable

The simple operation and relatively limited features of the arbor press make it an affordable option compared to other types of presses. If you’re purchasing a press for the first time, or you’re using the press infrequently, an arbor press will present faster ROI.

Disadvantage: Limited Features

The arbor press is somewhat small and easy to operate, but this can give it some limitations. Some important safety features are missing from arbor presses, and other missing features can make it difficult to take on more complex maneuvers.

Disadvantage: Limited Applications

If you end up working with larger workpieces, different materials, or different applications, your arbor press might not be able to cut it. These limited applications may slow your operation or result in low-quality results for some jobs.

Disadvantage: Limited Growth Potential

Modern presses can give you in-depth information that can make your operation faster and more efficient. The potential of arbor presses is more limited; using data-gathering features, speeding up production, and improving process efficiency generally isn’t always an option for arbor presses.

Disadvantage: Inconsistency

Arbor presses rely on manual operation, which can introduce inconsistencies. For certain applications, it is easy to see if the job has been completed correctly, but for pressing applications that require higher levels of precision, it may be difficult to determine by eye.

Disadvantage: Potential for Injury

Though easy to operate, an arbor press requires the same manual action from the operator for each and every cycle. This repetitive action, performed many times a day, can lead to repetitive stress injuries, which can become very serious and cause permanent disability.

Air Press

An air press or pneumatic press is more advanced, and these additional features can offer a number of benefits. An air press can be a great step up if you find that your manual press isn’t as effective as it used to be, or it can be a good foundational press to start with.

Advantage: Compact Design

Air presses are generally larger than arbor presses, but still present a small footprint. Pneumatic presses are designed to sit on workbenches as well, so they don’t require dedicated floor space, like hydraulic presses.

Advantage: Versatile Applications

The force and configuration of air presses is adjustable in many ways, giving them a wide array of applications. With up to 2.5 tons of force, air presses are suitable for many different assembly applications like riveting, swaging, forming, staking, marking, and other jobs.

Advantage: Easy to Maintain

Using compressed air to magnify force allows the air press to operate in a relatively clean and efficient manner. There’s no additional lubricant or oil required, such as that required for hydraulic press maintenance. Simply maintaining the machine and the air lines will keep the press operating efficiently for years to come.

Advantage: Advanced Features Available

Though they’re not mandatory, air presses can be equipped with many advanced features that aren’t available for arbor presses. These features can enable faster operation, increase safety, reduce defects, and allow operators to detect issues before they cause slow-downs or shut-downs.

Disadvantage: Investment in Factory Air

If your operation is not currently set up with factory air supply, adding a pneumatic system may require additional investment. However, this can also be seen as a growth opportunity, providing the ability to incorporate more energy efficient pneumatic presses into your press lineup.

Disadvantage: Limited Power

Air presses supply force that is equivalent to many arbor presses. However, hydropneumatic and hydraulic presses can supply much more force, with some providing hundreds of tons of force. For these types of heavy-duty applications, an air press might not be sufficient, and a hydraulic or hydropneumatic press might be ideal.

When it comes to deciding between an air press and an arbor press, understanding these advantages and disadvantages can help. If you have questions about which press would be best for your production, contact us. We’re happy to give you more information about each press available for the applications you’re working with.

Need a production air press, fit for your job or project?

Give us a few details and we will quote the best press for the application.