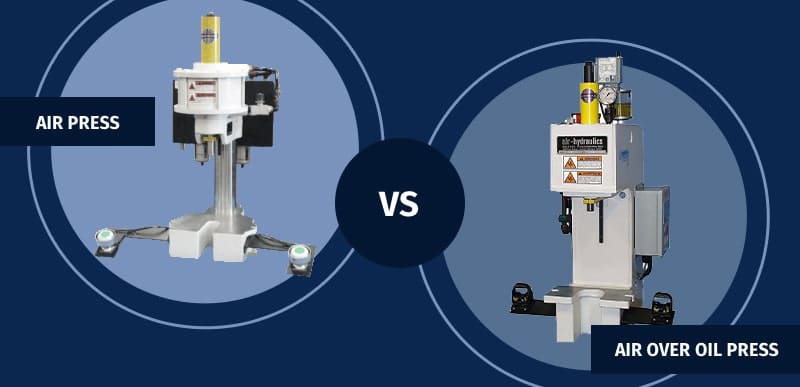

When it comes to tough assembly and metalforming jobs, a great factory press is an essential tool. But, there are many different types of presses to choose from. Two of the more affordable and easily usable types of industrial presses are air presses (AKA pneumatic presses) and air over oil presses (AKA hydropneumatic presses). So, what’s the difference between an air press vs an air over oil press?

Air Press vs Air Over Oil Press: What’s the Difference?

What is an Air Press?

An air press and an air over oil press are similar, but there are some important differences. An air press, or pneumatic press, uses compressed air in a series of cylinders to create force. The compressed gas contained in the cylinder can be regular air, mostly nitrogen and oxygen, or compressed nitrogen. When the air is compressed further in the cylinder, it creates pressure anywhere between 10psi and 5,000psi, which can then be used for a wide variety of assembly applications, riveting, punching, forming and other jobs.

What is an Air Over Oil Press?

An air over oil press, or hydropneumatic press, uses hydraulic and pneumatic technology to create force. This system uses compressed air to drive a piston that compresses hydraulic fluid. These technologies combined can create even more force than a pneumatic press, and can create force comparable to a full hydraulic press.

Air Press vs Air Over Oil Press: How Are They Similar?

Air presses and air over oil presses are similar in many ways. Both use pneumatic technology to create force. They also operate in similar ways, and have similar safety mechanisms and features. An air press and an air over oil press both require similar power needs, and have similar maintenance schedules. Compared to a purely hydraulic press, the air press and air over oil press also have less intense maintenance schedules.

Comparing an air press vs air over oil press, there are a few similarities:

- Both use compressed air to generate force

- Similar maintenance schedules

- Similar power requirements

- Similar safety mechanisms

- Similar operation

Air Press Vs Air Over Oil Press: How Are They Different?

Though there are many similarities, there are also several important differences between an air press and an air over oil press. Since it uses hydraulic technology combined with compressed air, the air over oil press can exert more maximum pressure than a purely pneumatic press. An air press can exert between 150 and 5,000 lbs (2.5 tons) of force, while an air over oil press can exert between 2.5 and 50 tons of force. For this reason, an air press and an air over oil press are each ideal for different jobs and applications. An air press may be used for light applications like assembly, riveting, punching, staking, stamping, crimping, and similar tasks. An air over oil press may be used for heavier applications like bushing and bearing insertion, stud insertion, broaching, swaging, trimming, notching, and similar tasks.

Browse information and recommended presses by Industrial Press Application >

Another important difference between an air press vs an air over oil press is the costs associated with each. While they have similar maintenance schedules and costs to maintain, an air over oil press can exert more force and costs more to purchase. However, an air over oil press is generally more affordable than a purely hydraulic press. Finally, an air over oil press will be slightly larger and take up more space in your shop than an air press.

Comparing an air press vs air over oil press, there are a number of important differences:

- An air over oil press can exert more maximum force than an air press

- Each press is ideal for different jobs

- An air over oil press costs more to purchase than an air press

- An air over oil press has a larger footprint than an air press

Both an air press and an air over oil press have similarities as well as important differences. Which one is right for your shop will depend on your primary application, your budget, your shop layout, and more. If you’re unsure which type of press is right for you, contact us. We can help you find the right fit for your needs.