An air-over-oil press uses a combination of compressed air and hydraulic fluid, to enhance the power of a pneumatically operated press, with the consistent fluid pressing action found in fully hydraulic presses. Air-over-oil press technology accomplishes the increase in power without the use of high voltage power units or incorporating noisy pumps and motors, making this an safer, more efficient and less maintenance intensive option compared to hydraulically powered press machinery.

So how does an air-over-oil press work? And what are the benefits of using an air-over-oil press? Understanding the operation and benefits can help you determine whether an air-over-oil press is right for your next application project.

How Does an Air-Over-Oil Press Work?

An air-over-oil press, also known as a hydropneumatic press, uses both pneumatic and hydraulic technology to drive the press. There are several distinct advantages of an air-over-oil press, which we’ll discuss later in the blog post. But first, how does a typical air-over-oil press actually work? Let’s go through the basic operation of a hydropneumatic press, step-by-step.

- First, the operator loads the parts or material into the machine and prepares the operation.

- The operator then engages the machine, which energizes a pneumatic valve.

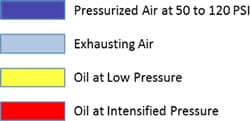

- Factory supplied air fills the cylinder, advancing the internal reservoir piston which displaces self-contained oil on the working piston, initiating a rapid advance low-force stroke.

- Upon reaching the workpiece or a preset distance, a secondary power control valve is energized. This initiates the internal high pressure piston by compressing the self-contained hydraulic oil onto the working piston, producing a smooth and powerful hydraulic intensified stroke. This intensified stroke is referred to as the power stroke and is typically .500” in most systems. It can be initiated anywhere within the overall stroke of the cylinder.

- When the operation is complete, both valves are de-energized and the rod returns to its original position.

The compressed air and oil work cooperatively to extend a smooth and consistent force throughout the machine press cycle. Though this description is a simplification, it outlines the general operation of the air-over-oil presses you can regularly find on the marketplace, like our AH-Series Hydropneumatic Press shown above, featuring models that deliver from 4 to 50 tons of force – a great option for the following applications:

Air Hydraulics C-Series Air-Over-Oil Press

Then there is another, less known type of air-over-oil press, our Air-Hydraulics Press, which we refer to as our C-Series Air-Over-Oil line. These presses are uniquely designed to deliver a full length hydraulic intensified power stroke, as opposed to just a limited .500” power stroke. This is accomplished by energizing a single pneumatic or electric power valve to shift and actuate the press’ booster cylinder, compressing the self-contained hydraulics fluid directly into a separate working cylinder (ram cylinder) to intensify the entire press working stroke, just like a full hydraulic press, only powered by factory supplied air.

These presses are great for heavier applications requiring full force at over half an inch in distance, such as:

-

- Bushing or Bearing Insertion

- Press-Fit Assembly

- Stud Insertion

You can purchase a hydraulic intensified booster cylinder individually to power your custom press machinery.

See how it works »

Advantages of an Air-Over-Oil Press

Now that you know how two different types of air-over-oil presses work, let’s take a look at the advantages of this press technology. Air-over-oil presses offer unique advantages compared to purely pneumatic and fully hydraulic presses. Air-over-oil presses can offer increased control and efficiency compared hydraulic presses and the hydraulic technology also offers additional power compared to many purely pneumatic presses. The combination of technologies also provides a smoother operation, which can be very advantageous for processes that require higher levels of accuracy and control. Look over the following advantages of air-over-oil presses to see if they may better fit your particular operation.

Advantages of Air-Over-Oil Presses Include:

- Increased Power – using self-contained hydraulic fluid power, higher force ranges can be achieved with minimal air consumption. (Up to 50+ tons with our AH-Series and up to 15 tons with the Air Hydraulics C-Series Press)

- Safer – The control package for these air-over-oil press packages only require an airline connection or 120vac power to operate, unlike standard hydraulics presses which require a high-voltage power source.

- Energy efficient – Without the constant power draw of hydraulic pumps and motors, air-over-oil presses require less energy to operate than standard hydraulic presses.

- Quieter – Air-over-oil presses do not require the use of noisy pumps and motors, so they are much quieter than standard hydraulic presses. A small amount of exhausting air is the only noise heard during the actual cycling of the press.

- Less maintenance – Air-over-oil presses require less maintenance than full hydraulic presses. Less maintenance equals less downtime, and more time for production.

- Versatile – Air-over-oil presses are not limited in configuration and can be modified and designed to fit an array of application requirements

- Cost-effective –In addition to being easier to maintain, air-over-oil presses also are much more affordable than full hydraulic presses, meaning a better return on your initial investment.

The right designs and configurations of an air-over-oil press can further optimize production for a specific application. If you’re looking for a powerful new press for your shop or factory, contact us. We can help you find or design a press that is powerful, cost-effective, and efficient. If you have questions about air-over-oil presses or other press designs, we’re happy to help.