50 tons of pressing power is enough to accomplish a wide variety of shop and factory tasks. Whether you’re looking for a 50-ton press for odd jobs around your shop, or a factory press for production, there are a number of options to choose from. Let’s take a look at different industrial presses for 50-ton applications.

Industrial Presses for 50-Ton Applications

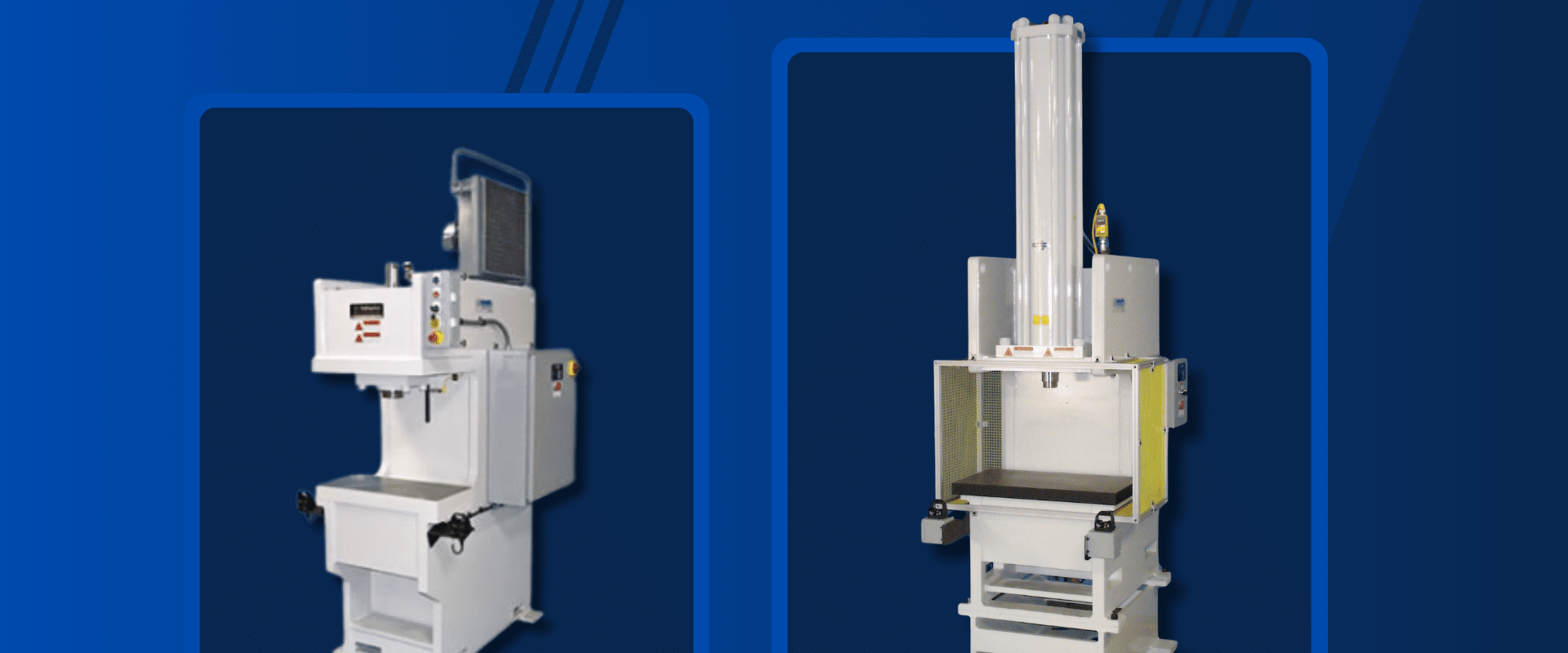

A 50-ton press is a heavy-duty machine designed to apply 50 tons of force to shape, mold, cut, form or stamp materials, and/or assemble components. These presses come in different types depending on the power source and application, such as hydraulic, mechanical, or hydropneumatic presses.

Types of 50-Ton Presses:

- Hydraulic Presses: Using fluid power to generate force, hydraulic presses allow for precise pressure control and fluid movement. They are ideal for heavy-duty forming, bending, and punching applications, but they demand a great deal of maintenance and care to operate properly.

- Mechanical Presses: These presses use a mechanical flywheel and crank system, offering faster cycles but with less control over the force applied. These presses can be demanding on the operator, especially when they’re used for complex or repetitive tasks.

- Hydropneumatic Presses: Also called air-over-oil presses, hydropneumatic presses combine the power of compressed air and compressed fluid to generate a great deal of force. Hydropneumatic presses can easily reach 50 tons of force, and require less maintenance than fully hydraulic presses.

- Servo Presses: A variety of different presses can use servo motors. A servo motor controls the press action, allowing for greater precision, energy efficiency, and programmability.

50-Ton Press Applications

Not all jobs require 50 tons of force. 50-ton presses are usually needed for heavy-duty operations around shaping, cutting, and forming metals. They can also be used for some assembly operations, such as press-fitting parts together so they aren’t separable.

The following is not an exhaustive list of 50-ton press applications, but includes some of the most common jobs:

- Metal Forming: Bending, stamping, drawing, and punching metal parts.

- Molding: Heavy duty presses are sometimes used in plastics or composites to create molded parts.

- Assembly: Used to press-fit parts together, such as bearings or bushings.

- Cutting: Presses can be used for die-cutting materials like sheet metal or rubber.

- Forging: A 50-ton press is powerful enough for small to medium forging operations, especially for forming metal parts.

Choosing a Press for 50-Ton Applications

With a variety of options to choose from for 50-ton applications, it can be difficult to know where to start. Here are a few considerations to keep in mind, and a list to run through when choosing the right press.

- Type of Material: Different materials require different forces and press types. For example, a hydraulic press might be needed for thick metal, while a servo press is ideal for precision work on thinner metals. A few shorthand equations can help you determine

- Tooling Compatibility: Ensure that the press can be fitted with the appropriate dies or tooling for your tasks. Mechanical, hydraulic, and hydropneumatic presses with different configurations and sizes will be able to work with different types of tooling.

- Energy Efficiency: 50-ton hydraulic presses use the most energy, while servo electric, hydropneumatic and mechanical presses use substantially less. For high-volume jobs and long periods of use, consider a more energy efficient press.

- Precise Control: Some presses, especially servo presses, offer highly accurate positioning and force control, reducing waste and increasing efficiency.

- Compact Design: Air-over-oil presses and air presses are generally more compact than full hydraulic presses, as they use compressed air to drive parts of the system.

- Complexity: Consider the complexity of the job you’re performing. Will your press perform the same job repetitively, or will it need to switch between different jobs? Presses configured with rotary index tables will be able to perform more complex jobs.

- Higher Cost: Servo electric and hydraulic presses are typically the most expensive, and are also more expensive to maintain, while hydropneumatic presses are typically less expensive and are easier to maintain.

- Control Systems: A variety of programmable controls offer many different features and functions, such as the ability to automate cycles and monitor performance.

- Safety Mechanisms: Safety features like guards, light curtains, and emergency stops are critical for factory environments, and allow for faster, easier, safer use.

Choosing the right industrial press for 50-ton applications can be a challenge. If you’re unsure which type of press is right for you, or which features can make your production more efficient, we can help. Contact us today to learn more about any press and get a quote.