Case ID: 9729

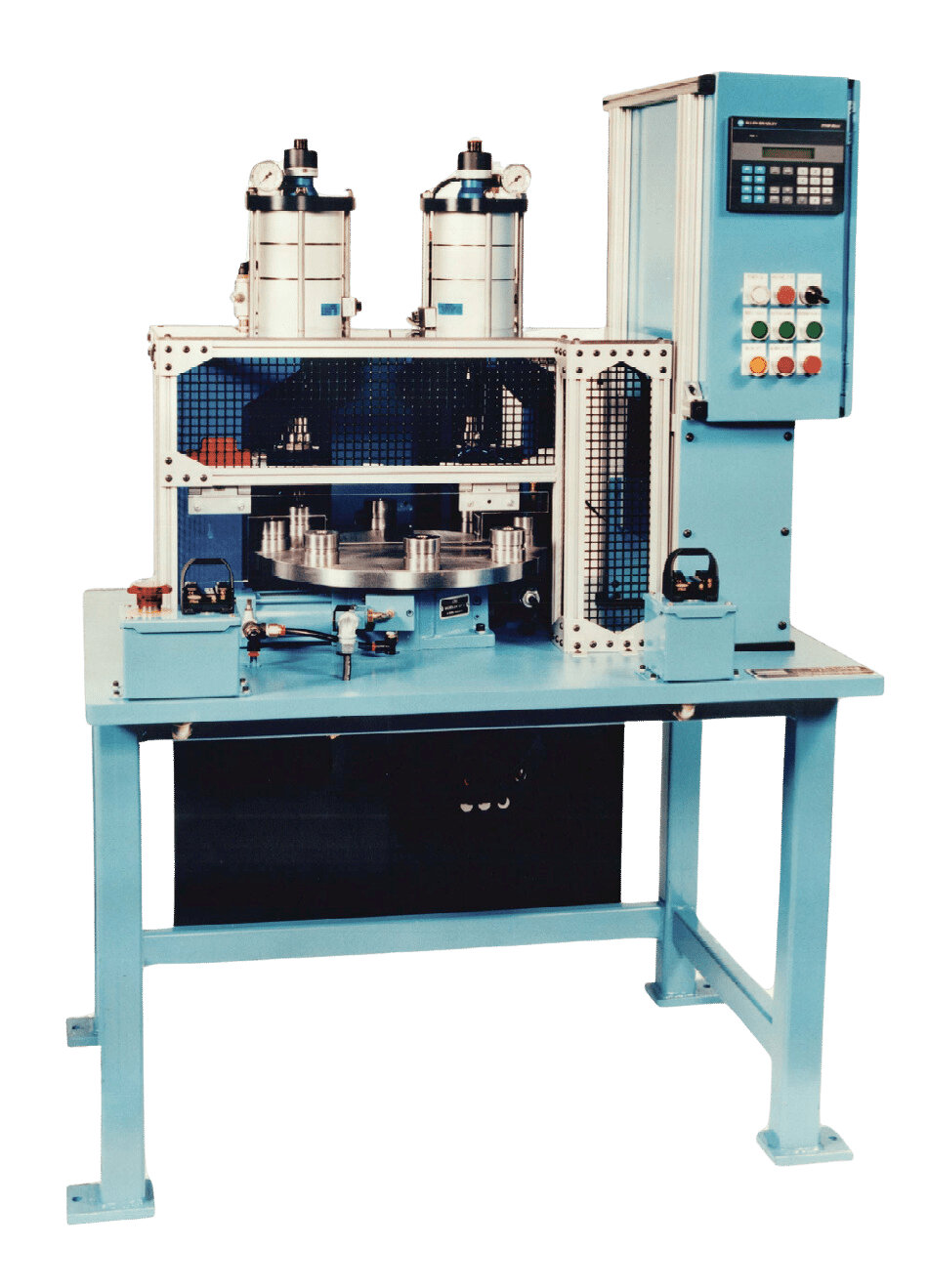

Application Details: For this custom designed indexing machine, the operator simply needs to initiate the automatic cycle and load parts continuously onto the part fixtures. The indexer automatically cycles each part to the pre-crimping station and then to the final crimp station. After the final crimp station, the part is indexed to the unload station where it is ejected into a tote by an air blow off device.

| Requirement: | Manufacture a high production turnkey pressing machine to crimp small metal identification “Shell Can” lids |

| Solution: | Semi-Automatic Two-Stage Air Press Crimping Machine with Rotary Indexing Table and Air Blow Feature for Unloading |

This fully automated indexing press allows consistent press crimping and alignment, providing a significant increase in overall production speed and quality by reducing load times and human error.

| Press Model | Two Custom Designed 2-Ton Air Presses with Model 1092-8 Station Indexing Table |

| Application | Crimping / Forming |

| Press Features |

|