Air-over-oil intensifiers, also known as air-oil boosters, are devices designed to amplify the force generated by a pneumatic system by utilizing hydraulic principles. These intensifiers play a crucial role in applications where a higher force is required than what a standard pneumatic system can deliver. Let’s take a look at how air-over-oil intensifiers work, and what benefits they can provide.

How Air-Over-Oil Intensifiers Work

Air-over-oil intensifiers use a combination of shop air, a pneumatic cylinder, and a hydraulic cylinder to intensify the force generated. Let’s see how this process works, step-by-step.

- Compressed air actuates the pneumatic cylinder, which, in turn, moves a piston.

- As the piston in the pneumatic cylinder moves, it displaces hydraulic fluid (oil) from the hydraulic cylinder.

- The hydraulic cylinder typically has a smaller diameter than the pneumatic cylinder. This size difference creates a force multiplication effect.

Pascal’s law dictates that the pressure in a confined fluid is transmitted equally in all directions. Therefore, the force applied to the large pneumatic piston transfers to the hydraulic piston, resulting in an increased force output. - The return stroke of the system is often accomplished using a spring or by allowing the compressed air to push the hydraulic fluid back into its reservoir.

- This allows for a force output on par with that of a hydraulic system within a half-inch power stroke, but with the speed advantages of a pneumatic system. Certain models can achieve a full length power stroke, like in our C-Series Air Hydraulic Presses.

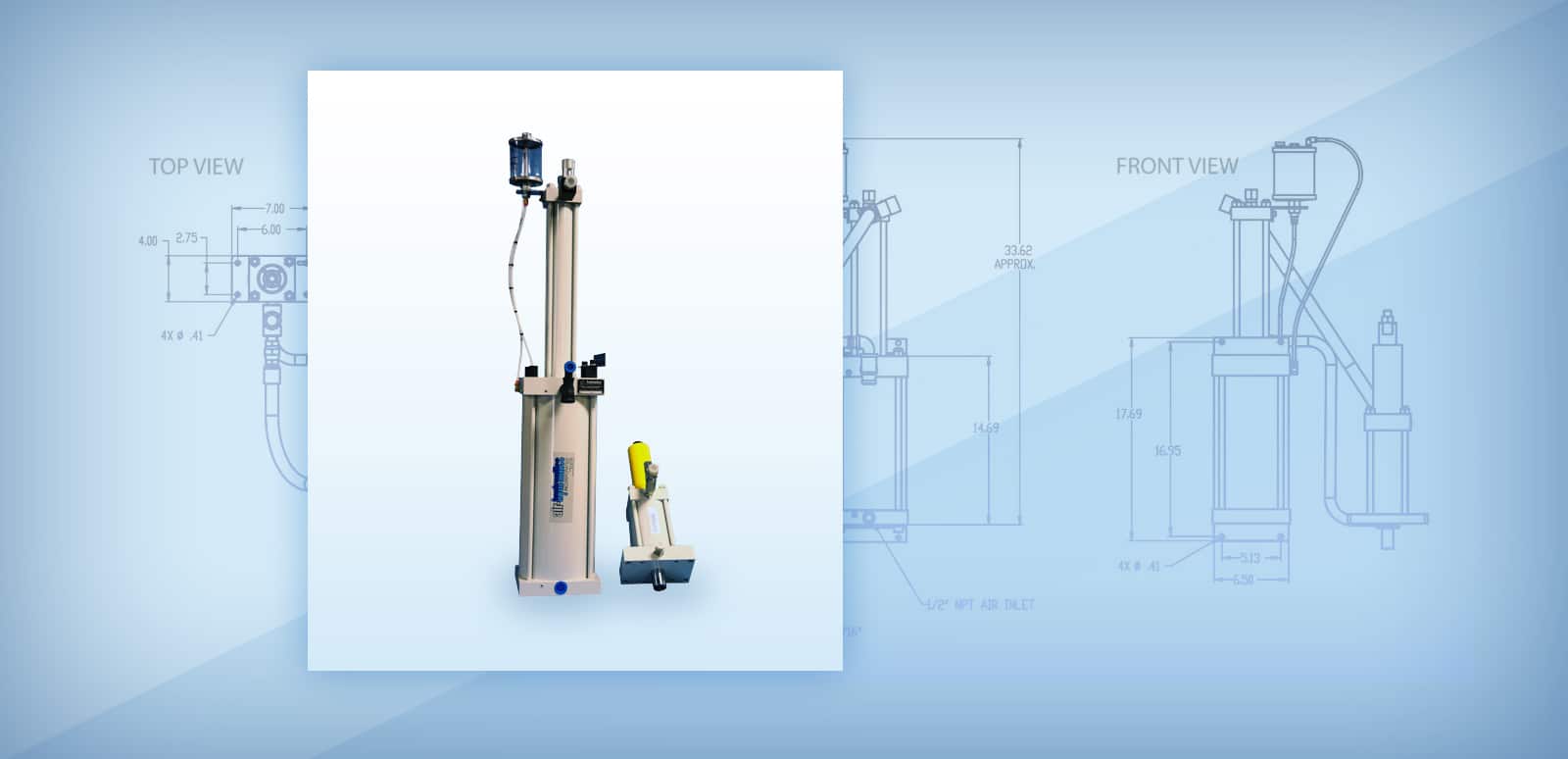

Air-Hydraulics offers two lines of Air-Over-Oil Intensifying Cylinders that use shop air to deliver between 2.5 tons to 50 tons of force. Learn more ›

Benefits of Air-Over-Oil Intensifiers

Air-over-oil intensifiers combine pneumatic speed and hydraulic force, giving them a number of functional and cost-saving benefits. Here are some key benefits of using an air-over-oil intensifier or air-oil booster.

1. Force Multiplication

The primary advantage of an air-over-oil intensifier is its ability to multiply force. By using the principles of hydraulic systems to amplify the force generated by compressed air, these intensifiers allow for higher forces than what a pure pneumatic system could achieve.

2. Increased Speed

3. Efficiency

The intensification of force allows for more efficient use of energy. With a relatively small input of compressed air, the system can produce a significant force output, making it energy-efficient for applications that require intermittent high force. By contrast, fully hydraulic systems demand high levels of energy.

4. Cost-Effective

Compared to a full hydraulic system, air-oil boosters are more cost-effective. They offer the benefits of hydraulic force multiplication without the need for a large and complex hydraulic system.

5. Flexibility

Air-oil boosters offer flexibility in terms of force control. The operator can adjust the force output by regulating the air pressure, providing versatility for different applications and materials.

6. Compact Design

Air-over-oil intensifiers often have a more compact design compared to traditional hydraulic systems. This compact size makes it possible to fit into small spaces, while still offering a high level of power and force.

7. Intermittent Use

Air-oil boosters are well-suited for applications that involve intermittent use of high force. While continuous operation may lead to heat buildup, in scenarios with occasional heavy-duty requirements, air-over-oil intensifiers offer an effective solution.

8. Reduced Hydraulic Infrastructure

Compared to a full hydraulic system, the infrastructure requirements for an air-over-oil intensifier are typically simpler. Essentially, air-over-oil cylinders need only shop air to operate and hold no more than 1-2 gallons of oil, whereas hydraulic systems rely on reservoirs of 25 gallons or more, which can take up a decent amount of space. Hydraulic systems also require a high voltage power source, as well as a high level of maintenance. Using air-over-oil boosters instead can reduce installation and maintenance costs.

Applications for Air-Over-Oil Intensifiers

Air-oil boosters can improve speed, productivity, and functionality for a variety of different press applications. Here are a few examples of jobs that can be ideal for an air-oil booster.

1. Metal Forming and Stamping

Air-over-oil intensifiers are commonly used in metal forming and stamping processes where high force is required for a short duration.

2. Assembly Operations

Some assembly tasks demand extra force during certain stages. The intensifier provides intermittent high force that can quickly and effectively accomplish these tasks.

3. Pressing and Riveting

Applications such as pressing and riveting, where force is critical for specific stages, can benefit from the force multiplication capabilities of intensifiers.

4. Materials Testing

In materials testing scenarios where controlled force application is necessary, air-over-oil intensifiers provide a balance between precision and efficiency.

While air-over-oil intensifiers offer unique advantages, it’s essential to carefully consider the specific requirements of the application. Factors such as the level of force needed, cycle frequency, and the balance between force and speed will influence the decision to use these intensifiers in a particular manufacturing or assembly setting.

Air-over-oil intensifiers provide a hybrid solution that leverages the advantages of both pneumatic and hydraulic systems. By combining compressed air for speed and hydraulic force multiplication, these devices are valuable in applications where a balance between force and speed is essential.

Interested in an Air-Hydraulics Air-Over-Oil Intensifying Cylinder?

We have two lines of air-powered hydropneumatic cylinders that deliver between 2.5 tons and 50 tons of intensified hydraulic force.