Reducing waste in production and assembly can help you reduce costs, improve efficiency, and improve environmental sustainability. These strategies vary widely from inventory management to manufacturing techniques to asset maintenance and more. Let’s take a closer look at a few effective strategies to help manufacturers reduce waste in production and assembly.

13 Ways to Reduce Waste in Production and Assembly

1. Conduct a Waste Audit

Before implementing any changes, a comprehensive waste audit will help you identify areas of waste generation and inefficiency in production and assembly processes. Your waste audit might include a variety of different aspects, including materials, energy usage, resource consumption and more. With this audit completed, you’ll have a list of inefficiencies to address and prioritize.

2. Embrace Lean Manufacturing Principles

Lean manufacturing focuses on eliminating waste and maximizing value through continuous improvement and process optimization. Adopting lean principles such as 5S (Sort, Set in order, Shine, Standardize, Sustain), just-in-time production, and value stream mapping can help streamline operations and reduce waste.

3. Equipment Upgrades

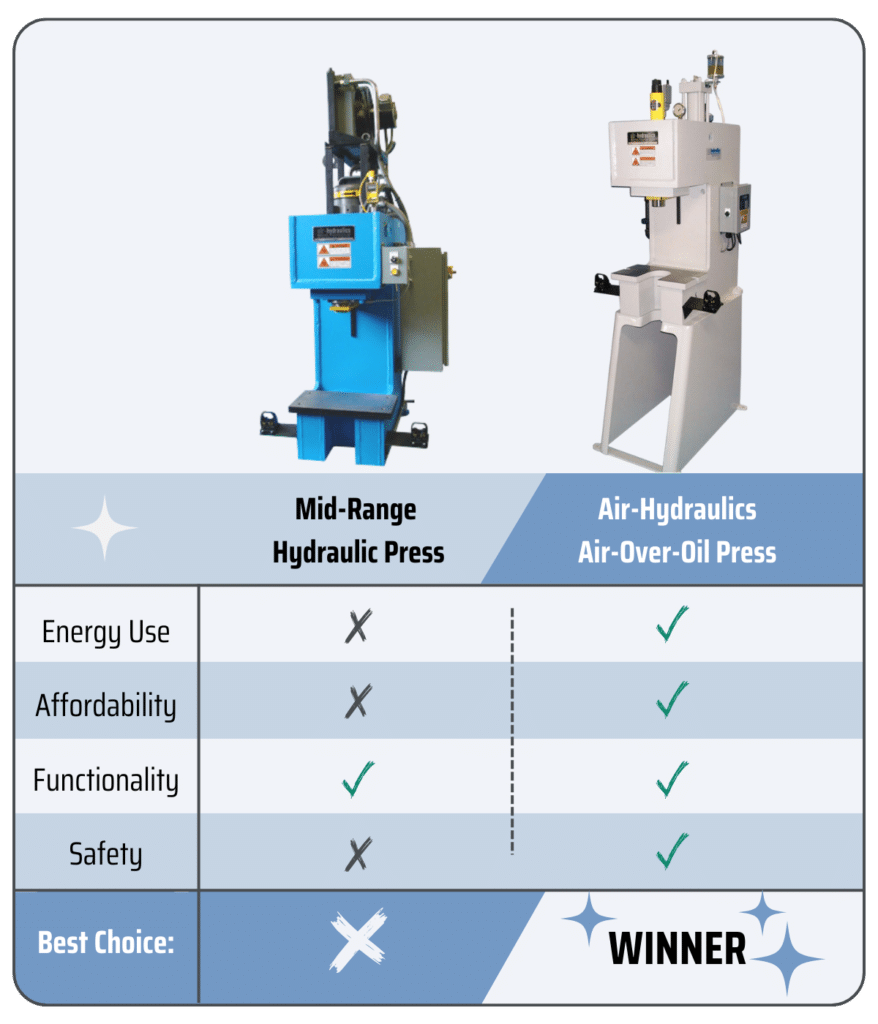

As technology advances, manufacturing equipment becomes more energy-efficient. As you might expect, older equipment tends to waste energy. This might occur due to maintenance issues such as air pressure loss in pneumatic presses, or simply using old, oversized presses that expend more energy than necessary. Upgrading your equipment can help you reduce waste in production significantly.

The Best New Technology for Factory Presses >

4. Identify Bottlenecks

Bottlenecks in your production process inevitably slow things down, and also cause waste to accumulate. Bottlenecks can cause machines to run idle while waiting for another machine to finish. Coordinating your machines’ run time can help reduce downtime and idle time overall, thereby also reducing energy waste and wasted time.

5. Adding Automation

Automation can help streamline some processes and use data to coordinate processes more efficiently. Automated upgrades can help move parts from one machine to another, coordinate sequential processes, reduce defects, and much more.

Simple automation like part indexing can help streamline production and assembly processes. Utilizing a rotary indexing table in your pressing applications also reduces the potential for human error in part positioning, decreasing the potential for defects dramatically.

View our 7-15” heavy duty, low profile Industrial Rotary Indexing Tables >

6. Optimize Inventory Management

Overstocking of materials and components can lead to unnecessary waste and tie up valuable resources. Implement inventory management systems to track inventory levels accurately and avoid excess stock. Just-in-time (JIT) inventory practices can help minimize waste by ensuring that materials are delivered precisely when needed for production.

7. Reduce Packaging Waste

Huge amounts of waste come from packaging. You can minimize the packaging waste from your business by using eco-friendly and recyclable materials, optimizing packaging design to reduce material usage, and implementing efficient packaging processes. You might also consider alternatives such as reusable packaging, biodegradable materials, and lightweight packaging solutions to minimize environmental impact. Working with material suppliers who are also eco-conscious can help reduce the packaging waste that reaches your business as well.

8. Implement Sustainable Material Practices

Choose sustainable materials and components whenever possible, prioritizing those with recycled content or renewable sources. Design products for disassembly and recycling to facilitate end-of-life disposal and minimize waste generation throughout the product lifecycle.

9. Invest in Energy Efficiency

Energy efficiency is one of the best ways to reduce waste in production and assembly. You can improve energy efficiency in your operations by optimizing manufacturing processes and/or implementing energy-saving technologies and equipment. Reduce energy consumption through measures such as using energy-efficient lighting, optimizing HVAC systems, and investing in renewable energy sources.

For processes that rely on hydraulic press equipment, upgrading to an energy efficient hydropneumatic press could cut production costs.

Take a look at our proprietary C-series Air-Over-Oil Press, for instance. This powerhouse machine is an energy saving alternative to a full hydraulic press that delivers full force throughout the stroke for heavier applications.

10. Train and Educate Employees

Employee engagement and training are crucial for successful waste reduction initiatives. Provide training on waste reduction techniques, sustainability practices, and the importance of minimizing waste. Encourage employee involvement in identifying opportunities for improvement and implementing waste reduction measures.

11. Collaborate with Suppliers and Partners

There are many ways you can reduce waste in your own operations, but you will have more options if you work with other waste-reducing partners. Work collaboratively with suppliers and partners to promote sustainable practices throughout the supply chain. Encourage suppliers to adopt eco-friendly packaging, reduce waste in their manufacturing processes, and prioritize sustainable sourcing practices.

12. Monitor and Measure Progress

It’s difficult to know how successful you are in reducing waste unless you monitor your process and set goals. Establish key performance indicators (KPIs) to track progress and measure the effectiveness of waste reduction efforts. Regularly monitor waste generation, recycling rates, energy consumption, and other relevant metrics to identify areas for further improvement and celebrate successes.

13. Continuous Improvement

Waste reduction is an ongoing process that requires continuous monitoring, evaluation, and improvement. Encourage a culture of innovation and continuous improvement within the organization, where employees are empowered to identify opportunities for waste reduction and implement sustainable solutions.

By implementing these strategies and embracing a culture of sustainability, businesses can reduce waste in production and assembly processes, minimize environmental impact, and create long-term value for both the company and the planet.