If your factory press isn’t performing up to your standards or you need to retool your press for a new operation, you might wonder if it can be refurbished or upgraded, or if it’s time for a replacement. It’s an important question that requires careful attention. Let’s take a look at a few situations and considerations for refurbishment, as well as when it’s time to get a new press.

Can Your Factory Press be Refurbished?

In many cases, while the idea of repairing or upgrading an existing press may seem like an opportunity to save on investment costs, it would actually end up costing more than it would to simply start fresh with new equipment. There are a few scenarios where upgrading a press will indeed be a cost-effective option, but there are a few important factors and limitations to consider.

Limited Refurbishment Options

First, refurbishment and upgrades are generally only performed by the original press manufacturer. Press manufacturers generally won’t take on the risk associated with reworking or upgrading another manufacturer’s work. Differing parts and standards make this process particularly difficult, and the results vary. Press manufacturers that maintain a high standard of workmanship will maintain and upgrade their own work, but won’t take chances with other manufacturers.

Situations for Refurbishment

A few situations are ideal for press refurbishment. You can still get a few more years out of your press if you’ve encountered these obstacles. Your OEM should be able to provide these upgrades and refurbishment options:

- Safety features: If your press is missing some critical safety features, refurbishment can provide improvements. Your existing press may be eligible for upgraded safety features to increase factory safety and/or bring your press up-to-code.

- Repairs: Regular press maintenance will help keep your press in full working order, but some parts will inevitably still wear down. Your OEM can provide parts for repair, or replace things like valves and cylinder seals, cylinders, and other wear parts. If you notice your press losing force or efficiency, replacing these wear parts can help.

- Updated controls: If the machine’s controls have become outdated, an upgrade refurbishment may help. Updating the control system can help the machine integrate with your factory, perform more efficiently, and work faster.

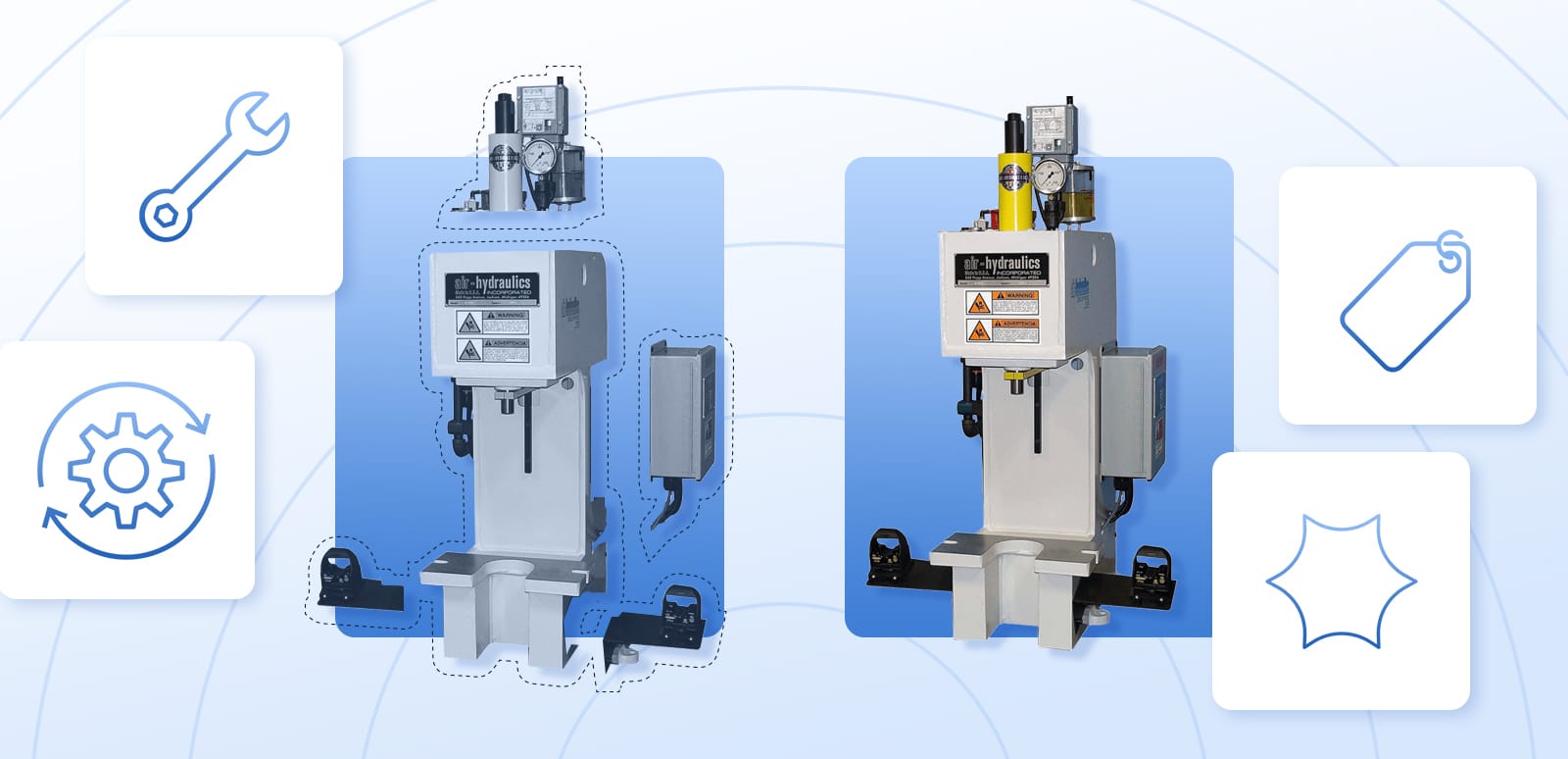

We gave 8 of our machines new life with rebuilt cylinders, new valves, updated safety features, and updated controls

Refurbishment Cost Analysis

A cost analysis will be important as you debate between refurbishment and replacement. It’s important to consider all of the costs incurred by refurbishment, and how long you expect your equipment to last after it’s been repaired or upgraded. If your machine is missing important features and components, it’s also important to consider the opportunity costs of operating without these tools.

- Shipping or delivery: To refurbish your equipment, you’ll need to get your press to your OEM and back, which can be costly.

- Remaining life: How much life does your press have, even if it is successfully refurbished? Does it make financial sense to invest in the machine with the remaining lifespan for your production use?

- Opportunity costs: Consider energy costs and efficiency losses of using the outdated press. If your press is holding back efficiency gains of your more modern equipment, it can add invisible expenses that might be harder to gauge.

- Most presses that are eligible for refurbishment will also need to have their controls updated to meet current safety standards by default. This cost will be included in the overall refurbishment package and could make refurbishment less cost effective than an investment in all new machinery.

Situations Requiring New Presses

In some situations, it will make more sense to replace your outdated press equipment with a new press. In these situations, it will be difficult and costly to upgrade your press to bring it up to modern standards. It may be impossible to make these upgrades, or it generally won’t make financial sense.

- Additional power: If your press isn’t providing enough force to successfully complete the job or jobs it requires, you’ll need a replacement press. To completely change the force capabilities of the press would require a complete reconstruction, and it will make more sense to purchase a modern press with the latest technology.

- Energy efficiency: Modern presses use energy more efficiently than older presses. Modernization can improve energy efficiency by as much as 35% for some presses. Utilizing an air-over-oil press instead of a purely hydraulic press, for example, can also reduce energy use significantly and make your factory a bit greener.

New Press Technology: Technology upgrades like force and distance monitoring and other data collecting equipment, PLC controls, or automations can help to reduce defects, improve production speed, reduce costs, and more. However, older presses might not be able to integrate with this technology, and a new press with this technology can give your factory significant modern advantages.

Need to upgrade a hydraulic press?

Take a look at an energy efficient alternative press that’s customizable for modern manufacturing, including data collection, automations and/or future expansion.

If you aren’t sure about refurbishment vs replacement when it comes to an Air-Hydraulics Presses, contact us. Tell us what you need from your equipment and how it currently functions and we can give you options for replacement or refurbishment.