There are many types of press fit applications, and many options to choose from when it comes to industrial presses. Let’s take a look at different types of press fit applications, and compare hydraulic presses and air-over-oil presses for different processes.

What Are Press Fit Applications?

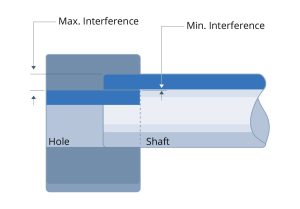

Press fit applications involve joining two components together by applying force to fit one part into another with an interference fit. Unlike threaded fasteners, adhesives, or welding, press fits rely on controlled force to create a secure, friction-based bond between parts. Press fits are common across many manufacturing and assembly processes where a strong, precise, and durable connection is required.

Types of Press Fit Applications

Press fits are widely used in a variety of industries such as automotive, aerospace, electronics, and general manufacturing. The installation of bearings into housings or onto shafts is a particularly common press fit application.

Bushings and sleeves are also frequently installed using press fits, enhancing wear resistance and structural integrity. In transmission systems, gears and pulleys are press-fit onto shafts to maintain alignment and power transfer efficiency. Additionally, electrical components like connectors and pins are often press-fit into circuit boards to create reliable electrical connections without the need for soldering.

- Bearing Installation: Ensuring tight and secure fits in housings or onto shafts.

- Bushing and Sleeve Installation: Pressing bushings into metal or plastic components for enhanced wear resistance.

- Gears and Pulleys: Fitting transmission components with precision.

- Electrical Components: Pressing connectors and pins into circuit boards.

Choosing the Right Press Matters

Selecting the right type of press for a press fit application is essential for achieving consistent results and preventing damage to your materials or components. With too little force, the parts might not form a secure connection, leading to misalignment or field failures. On the other hand, excessive force can deform or crack the components, increasing scrap rates and production costs.

Different applications also require different levels of force, speeds, and precision, so it’s important to choose a press that matches the demands of the operation. The right press not only ensures a strong and reliable fit, but also enhances production efficiency, reduces downtime, and minimizes waste.

Hydraulic Presses for Press Fit Applications

Hydraulic presses are widely used for press fit applications that require high force and precision. These presses use fluid pressure to generate force, allowing them to apply steady, controlled pressure throughout the pressing process. This makes them ideal for heavy-duty applications where both high force and high precision are important, such as installing large bearings, heavy-duty bushings, or other industrial components. Since hydraulic presses generate many tons of force, they are also well-suited for working with materials that require significant pressure to deform and fit securely.

Hydraulic presses use fluid pressure to generate high, consistent force, making them ideal for:

- Heavy-duty press fit applications: Bearings, bushings, and large industrial components.

- Precision force control: Hydraulic systems provide fine-tuned pressure adjustments.

- High-force applications: Capable of generating tons of force for large, high-strength

Disadvantages of Hydraulic Presses

Despite their advantages, hydraulic presses do have some drawbacks. Depending on pump and motor size, some presses tend to have slower cycle times because the system needs time to build and release pressure. Hydraulic presses also consume more energy compared to other types of presses, because the hydraulic system must run continuously. Their reliance on high-voltage energy and large reservoirs of hydraulic fluid or oil and loud, continuous noise can both present many safety hazards for operators.

Maintenance is another factor to consider. Hydraulic systems require more maintenance than many other presses, including regular fluid changes, seal replacements, and leak monitoring.

- Slower cycle times: Hydraulic systems require time to build and release pressure.

- Higher energy consumption: Continuous hydraulic pressure can lead to increased operating costs.

- Safety Concerns: High voltage energy combined with potential for hydraulic fluid / oil leakage creates potential for severe safety risks. Constant, loud operation can also be an issue for operators without proper ear protection.

- More maintenance: Regular fluid changes and system maintenance are necessary.

Air-Over-Oil Presses for Press Fit Applications

Air-over-oil presses, also known as hydropneumatic presses, offer a combination of compressed air and hydraulic fluid to provide controlled, high-force pressing without the space and energy demands of a full hydraulic system. These presses are ideal for medium-force press fit applications, such as installing bushings, bearings, and small-to-medium-sized components. Since they use air pressure for actuation, they often have faster cycle times than fully hydraulic presses, making them a great choice for high-volume production environments.

One of the biggest advantages of air-over-oil presses is their lower energy consumption compared to hydraulic presses. Since they use compressed air efficiently, they help reduce operating costs while still providing a high level of control. Air-over-oil presses are also generally smaller than hydraulic presses, and their compact size makes them a good fit for production environments where space is limited. Another important advantage is the price tag; air-over-oil presses are generally less expensive than comparable hydraulic presses.

- Medium-force press fit applications: Ideal for bushings, bearings, and small-to-medium-sized components.

- Faster cycle times: Air pressure allows for quicker actuation compared to hydraulic presses.

- Lower energy consumption: Uses compressed air efficiently, reducing operating costs.

- Safer than Hydraulic Presses: Pneumatic operation and smaller reservoirs of fluid and/or self-contained hydraulic operation removes the risk that comes with high-voltage energy power and potential for oil leaks. These presses are also quieter and only produce noise when in use.

- Compact footprint: Takes up less space than a traditional hydraulic press.

Disadvantages of an Air-Over-Oil Press

Air-over-oil presses have limitations as well. They cannot generate the same extremely high forces as hydraulic presses, which makes them less suitable for some very heavy-duty press fits. Additionally, while they offer better control than pneumatic presses, they may not provide the same level of fine-tuned pressure adjustment as a full hydraulic system.

- Lower maximum force: Not suitable for extremely high-force applications. These presses are typically used for applications that require less than 50 tons.

- Less precise than full hydraulics: While more controlled than pure pneumatic presses, they don’t always match the fine-tuned pressure control of hydraulics. For controlled pressure throughout the stroke, true hydraulic alternatives like our C-Series 2.5-15 Ton Air-Over-Oil Presses should be selected over typical fast-approach hydropneumatic presses.

Find the Right Press for Your Application

Choosing the right press for your press fit application is essential for ensuring efficiency, precision, and long-term durability. Working with press experts can help you navigate these choices and ensure that your investment aligns with your production goals. By selecting the right press for your specific needs, you can maximize efficiency, reduce waste, and improve the overall quality of your manufacturing process. Tell us about your press fit requirements, and we can help you find the press that will work best for you.