When we think of automation, we often think of multinational businesses, fully automated manufacturing, and enormous budgets. However, many smaller automation upgrades are helping businesses of all sizes realize important efficiency and productivity gains. Let’s take a look at a few comparatively simple automation upgrades that can help businesses take advantage of important efficiency upgrades.

Simple Automation Upgrades for Big Improvements in Manufacturing and Assembly

There are a wide variety of ways to automate time-consuming tasks to improve productivity in manufacturing and assembly across many different industries. As we examine some of these technologies, keep in mind that different businesses and applications will benefit from different automations. Automation upgrades are not one-size-fits-all, and will depend on your process, facility layout, goals, and more.

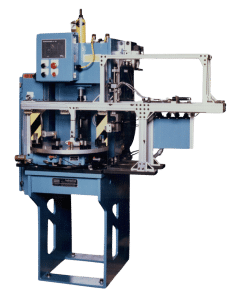

1. Rotary Index Tables

Rotary index tables are automated positioning devices that rotate and shift workpieces according to specific, predetermined steps in a production process. They provide a controlled, precise means of moving parts to different angles and positions, which means a worker doesn’t have to. This is ideal for applications which require multiple operations to be performed on a single workpiece in quick succession. Index tables can be powered by various mechanisms, including pneumatics, hydraulics, or electric motors, and certain models can be programmed to pause at set intervals to enable the necessary operations.

Rotary index tables are a relatively simple automation upgrade providing big improvements to many processes. The advantage of using rotary index tables lies in their ability to move parts quickly and accurately, reducing manual labor and ensuring consistent production quality. With their simple design, they can easily improve production speed and consistency for both simple and complex manufacturing or assembly tasks. By adding a rotary index table to a production line, operators can free up time to focus on other high-value tasks, while maintaining consistent quality across batches.

Presses with pneumatic rotary index tables like these two indexing machines above can improve your production significantly. Contact us to see how presses equipped with rotary index tables can support your unique application needs ›

2. Collaborative Robots (Cobots)

Collaborative robots, or “cobots,” are robots designed to work alongside human operators without the need for extensive safety barriers. Unlike traditional industrial robots that operate in isolated spaces, cobots are equipped with sensors and built-in safety features that allow them to detect and avoid obstacles. They’re typically programmed to handle repetitive tasks like lifting, sorting, and assembly.

Compared to traditional industrial robots, cobots are more affordable and require minimal setup. They’re easy to program, making them a great option for small companies looking to increase throughput and reduce worker fatigue. Cobots can also help companies adapt quickly to different jobs without the need for extensive retooling.

For example, a small auto parts manufacturer could implement cobots to handle part sorting and assembly. The cobots could assist in assembling small components like gears or springs, working alongside human workers who handle quality inspection or more complex tasks. The cobots relieve employees of repetitive motions, helping reduce fatigue and injury risks while increasing throughput.

3. Pick-and-Place Automation Systems

Pick-and-place systems are robotic arms or simple mechanisms that lift and move components from one location to another. These systems are typically equipped with grippers or suction devices to handle parts precisely and consistently. Pick-and-place automation is especially effective in high-volume manufacturing environments where consistent part placement is crucial, such as electronics assembly or packaging.

These systems are relatively simple to set up and can operate at high speeds, reducing the risk of human error and saving significant time on repetitive, manual tasks. They are particularly effective in industries like electronics assembly, where small components need to be moved and positioned accurately.

10 Ton Air-over-Oil Press with Rotary Index Table and Pick and Place Automation

4. Pneumatic or Hydraulic Presses with Basic Automation

Pneumatic or hydraulic presses are used across a wide variety of manufacturing processes, and a few simple automation upgrades can create big advantages. These machines use air or fluid pressure to apply consistent force, commonly used in shaping, bending, or compressing materials. With simple automation features, such as programmable controls for pressure and timing, manufacturers can achieve consistent press operations with minimal operator intervention. These presses are cost-effective for companies needing high-force operations without extensive setup.

Automation upgrades for presses can include programmable controls for pressure and duration, simple mechanisms to feed and remove materials from the press, and force and distance monitoring to reduce defects and improve quality. This setup enables consistent, reliable operation without requiring significant capital investment.

Learn more about precision control and automation for hydraulic, pneumatic, or hydropneumatic presses

Contact us >>

5. Modular Conveyors

Modular conveyors are adaptable conveyor systems that transport materials between workstations. They are composed of individual sections that can be rearranged or extended to fit changing production needs. Modular conveyors are a simple automation upgrade that can create big improvements for small manufacturers, allowing them to improve workflow efficiency without major infrastructure changes.

Modular conveyors are flexible, affordable, and easy to install, making them ideal for moving materials across a factory floor. They can be scaled up or down to meet production needs, making it easier to connect different production stations without manual intervention. With modular conveyors, companies can increase efficiency by reducing the amount of time workers spend transporting parts manually.

A series of welding stations at a manufacturing facility could use modular conveyors to components through different processes, then move the completed parts to the next process. This setup reduces the time spent manually carrying heavy materials, protecting workers from strain, streamlining the workflow and enabling workers to focus on skilled tasks like detailed finishing and assembly.

6. Vision-Guided Inspection Systems

Vision-guided inspection systems use cameras and image-processing algorithms to identify defects, verify part orientation, and confirm that a product or component was assembled properly. Often equipped with artificial intelligence, these systems analyze parts or products and flag any deviations from specified quality standards.

Automated vision systems equipped with cameras and machine learning algorithms are highly effective for quality control. These systems can identify defects, verify part positioning, and check for correct assembly with high accuracy and high speed. Vision systems are becoming more affordable and simpler to integrate, making them a valuable tool for ensuring product consistency without needing full-time quality control personnel.

Implementing even a few of these simple automation upgrades can significantly improve productivity, quality, and worker satisfaction. By leveraging cost-effective automation, small manufacturing companies can not only optimize their operations but also position themselves for future growth in a fast-moving industrial environment. To learn more about improving your factory presses with automation upgrades, contact us today.