A 10-ton hydraulic press is one of the most common types of presses on the market, but it’s also one of the more expensive and demanding presses in terms of upkeep and energy use. Many shops and factories would like a less demanding alternative, but aren’t sure where to look or how to find one, but we have the perfect alternative to a 10-ton hydraulic press right here. In this blog post, we’ll discuss how our Air-Hydraulic’s C-Series, Air-Over-Oil press compares to mid-range hydraulic presses from 2.5 to 15 tons.

First, let’s go over the key offerings of a mid-range Hydraulic press so we can understand the uses and benefits of this equipment.

What is a Mid-Range Hydraulic Press?

Hydraulic presses use compressed hydraulic fluid and a high-voltage power supply to generate force. Hydraulic presses vary widely in their force ranges, with the largest hydraulic presses reaching a whopping 80,000 ton capacity. Mid-range hydraulic presses are widely used across a variety of applications, and may include presses from 2.5 tons to 15 tons of force. With hydraulic press equipment, full force is typically applied throughout the entire stroke, making them suitable for heavier assembly and manufacturing applications that require high force at longer distances, e.g. bushing and bearing installation, stud installation, press-fit applications and more.

Hydraulic presses are one of the older types of presses, and are still considered the norm for many applications. Though the hydraulic press is widely considered the leading press type when it comes to force capacity, other press alternatives can offer energy-savings, improved safety precautions, and more efficiency overall.

What is a Hydopneumatic Press?

The hydropneumatic press, also known as the air-over-oil press, uses a combination of pneumatic and hydraulic power to deliver press force.Primarily pneumatic powered, these presses require less oil and significantly less energy to operate. Yet the boost from the added hydraulic power creates force on par with fully hydraulic presses that can be used across a variety of applications. Since most hydropneumatic presses apply hydraulic intensified power to a portion of the overall stroke, resulting in a power stroke of full force within a certain distance, typically ½ inch, these presses are generally considered suitable for assembly and manufacturing applications such as clinching, riveting, swaging, etc.

What is The AirHydraulics C-Series Air-Over-Oil Press?

Our C-series air-over oil press is designed for optimal usability. The press was first developed after WW2 when American manufacturing was in its post-war “boom”, and has proven to be a valuable alternative to hydraulic presses ever since. Models are available in four sizes ranging from 2.5 ton to 15 ton capacity, and can be mounted on a floor stand or a bench top machine base. Delivering full force throughout the entire stroke with the same combination of pneumatic and hydraulic power found in other hydropneumatic presses, there are virtually no limits on press applications the C-series air-over-oil press can perform. Read on to understand more about this particular press and how it is the best mid-range hydraulic press alternative.

Interested in an alternative to a 10-ton hydraulic press?

Talk with our experts ›

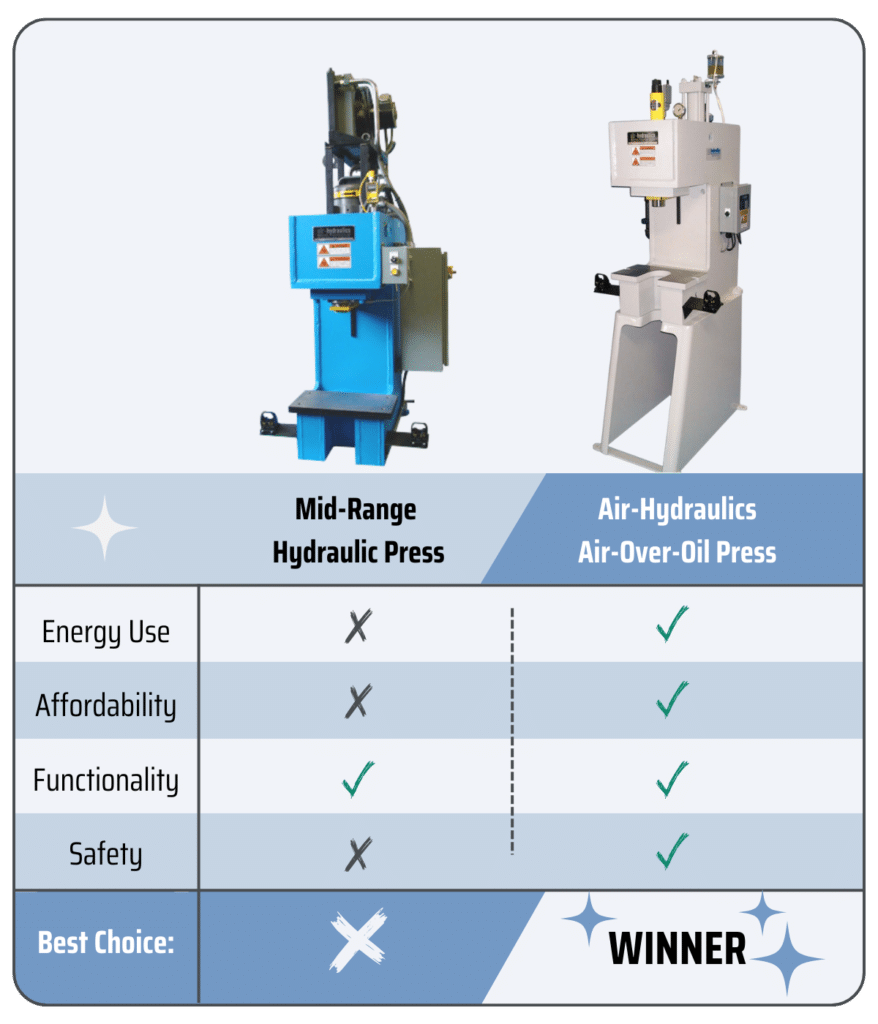

The C-Series Air-Over-Oil Press vs. Mid-Range Hydraulic Press

Let’s compare the C-Series Air-Over-Oil Press to a standard mid-range Hydraulic Press across the top factors for overall performance and efficiency.

Energy Use

As energy costs and sustainability concerns increase, many shops and factories are looking for ways to decrease energy use significantly. Hydropneumatic presses like the Air-Hydraulics Press provide the same pressing power as hydraulic, but without the intensive energy demands.

While most hydraulic presses typically require high voltage 240/480V electricity to function, hydropneumatic equipment can be run solely on factory compressed air. Also, whereas a hydraulic motor is always on and constantly drawing power for operation, an air-over-oil press only requires energy during the cycling process, leading to far less energy use overall. Hydropneumatic presses also use substantially less oil to operate, which is evidenced by the reservoir for these systems being a fraction of the size needed for hydraulic. When taking these separate considerations together, the air-over-oil press is a clear winner in terms of energy conservation.

Affordability

Hydropneumatic presses generally require less initial investment than their hydraulic counterparts, and the total cost of ownership is also substantially lower. Hydraulic presses require more regular maintenance to ensure they stay in full working order. While hydropneumatic presses also require regular maintenance, the demands are minimal. Since hydropneumatic presses don’t require a high-voltage power supply, they also reduce energy costs substantially, leading to a much lower operation costs over time in addition to the initial investment savings compared to full hydraulic.

Functionality

The belief that high force and functionally can only be found with hydraulic press equipment is a common misconception. Hydraulic and hydropneumatic presses can each provide exceptional force, and are able to accomplish a wide variety of shaping, forming, punching, press fit, and many other jobs.

Getting the right-sized press for your job is key to overall efficiency, and choosing an over-sized press will only lead to over-sized energy costs. When it comes to functionality, a hydraulic press and a hydropneumatic press both provide speed, efficiency, and versatility, and when it comes to options for mid-sized press equipment, you can find the same level of functionality between hydraulic and hydropneumatic presses for nearly any assembly or manufacturing application.

Safety

Hydraulic presses pose some safety hazards and require a few additional safety precautions to operate safely. Since hydraulic presses require a high-voltage power supply, it’s critical that they are wired and grounded properly, and that all electrical cords and outlets are undamaged and regularly inspected to ensure optimal safety.

The use of large amounts of hydraulic fluid also presents a fire hazard, and with the combination of oil and high voltage electricity, any sparks or excessive friction must be prevented. Hydropneumatic presses do not come with the same safety concerns. Using minimal oil and lower voltage, or no electricity at all, there is essentially no risk of fire or explosion. Finally, hydraulic presses are very loud during operation, which can cause hearing damage without careful safety measures in place, whereas hydropneumatic counterparts are very quiet by comparison. For these reasons, many shops and factories prefer hydropneumatic presses for higher overall safety of their operations.

As you can see, hydropneumatic press options beat full hydraulic in the mid-range category for energy use, affordability and safety while offering the same range of functionality, making our C-series air-over-oil presses the clear winner in a side-by-side comparison and the perfect alternative for hydraulic presses up to 15-tons.

Looking for an Alternative to a 10-Ton Hydraulic Press?

Air Hydraulics offers several press models that offer substantial reduction to energy use, greater efficiency and overall cost savings compared to hydraulic equipment. Get in touch with us to learn more.