Air-powered presses, including pneumatic presses and hydropneumatic presses, are commonly used for production and assembly applications in factories. They rely on compressed air to generate the force needed to carry out tasks like punching, stamping, bending, forming, and assembly. Air presses are popular for their simplicity, speed, and cost-effectiveness. Let’s take a closer look at air-powered presses for production and assembly, including how they work, their ideal applications, and their advantages.

How Do Air-Powered Presses Work?

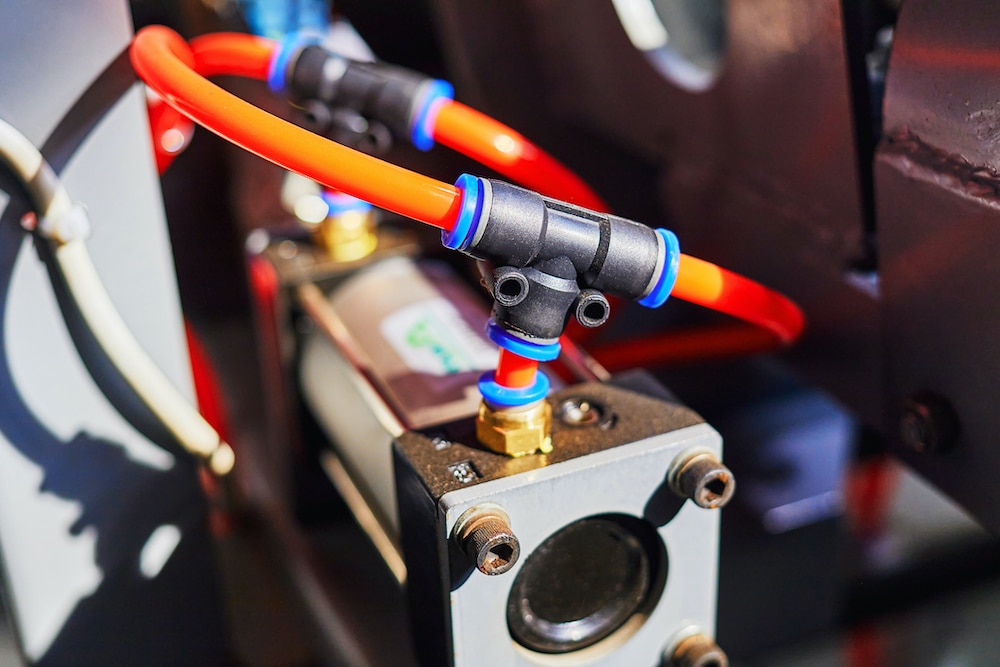

A pneumatic press uses the power of compressed air to perform industrial tasks. The process starts with an air compressor that generates and stores compressed air at a set pressure. A series of control valves regulate the flow and timing of air entering the press’s pneumatic cylinder. When the operator activates the press, either through a manual switch or an automated system, the control valves shift, allowing compressed air to enter the cylinder and push against a piston.

As the compressed air pushes the piston downward, it moves the ram toward the workpiece. This ram applies the force needed to perform the pressing action, whether it’s punching a hole, bending metal, or assembling parts. The force generated by the press is determined by the air pressure and the size of the pneumatic cylinder.

Once the pressing task is complete, the control valve changes the direction of the air or releases it. This change in air direction or drop in pressure causes the piston and ram to retract to their starting positions, either aided by return springs or by air pressure applied to the opposite side of the piston. The press is then ready for another cycle, allowing for quick, repetitive operations with minimal downtime.

The simplicity and speed make pneumatic presses an efficient choice for many factory assembly and production tasks, especially where precision and heavy force are not the primary requirements.

AHI Industrial Air Presses

Air-Hydraulics offers two lines of pneumatic air presses for industrial production and assembly applications.

Each press model can be fully customized with specific controls, safety features or automations to meet your applications needs and requirements.

Hydropneumatic Presses: Air-Over-Oil

A hydropneumatic press, also known as an air-over-oil press, combines both pneumatic and hydraulic systems to deliver power with efficiency. Much like in a standard pneumatic press, the process behind a hydropneumatic press also begins with compressed air. The compressed air enters the pneumatic cylinder and pushes a piston downward, displacing the self-contained hydraulic fluid on the output piston rod. This allows for a low-force, quick approach to the workpiece which generates quicker cycle times while being energy efficient.

Once the press ram reaches the workpiece, the second stage of the process begins. The compressed air is then directed into another air cylinder chamber, which advances the internal hydraulic pressure piston and rod into the self-contained hydraulic fluid, intensifying pressure onto the output piston rod. This amplifies the force significantly, allowing the cylinder to exert the required force on the workpiece. In this way, hydropneumatic presses are ideal for tasks requiring both speed and power, such as metal forming, punching, or assembly operations involving dense materials.

Applications of Air-Powered Presses

Though air presses can deliver a great deal of force, most air presses do not exert as much force as hydraulic presses. Hydropneumatic presses can exert more power than purely pneumatic presses due to the internal hydraulic intensification. This makes it possible for air presses and air-over-oil to accomplish a wide variety of applications.

Industrial air presses are widely used in assembling car parts, such as pressing bearings or assembling electrical connectors. Air presses are also commonly used in electronics manufacturing, since they can be lightweight, fast, and clean. They may also be used in packaging lines to seal, clamp, or assemble components quickly, or in plastic part assembly or forming.

The following are a few common examples of air powered presses in product and assembly operations:

- Press-Fitting: Inserting or pressing components into place, such as bearings, bushings, or fasteners in automotive and electronic assembly.

- Riveting and Crimping: Joining materials, such as riveting sheet metal or crimping electrical connectors.

- Punching and Stamping: Creating holes or shaping materials, especially in lighter materials like sheet metal, plastic, or rubber.

- Bending and Forming: Manipulating materials into the desired shape, especially for materials like sheet metal or softer materials.

- Sealing and Clamping: Joining materials together by folding or pressing, especially for packaging or clamping components together.

Advantages and Disadvantages of Air Presses in Factory Settings

There are a variety of advantages of air presses, including pneumatic and hydropneumatic presses. There are also some disadvantages that make them unsuitable for some operations. Let’s take a closer look at each.

Advantages:

- Simplicity and Low Maintenance: Both pneumatic and hydropneumatic systems are relatively simple and have fewer moving parts compared to hydraulic systems. This reduces the amount of maintenance required.

- Energy Efficiency: Air presses consume less energy than hydraulic presses, since they don’t require a continuously running pump like hydraulic systems. This makes them efficient for high-cycle, intermittent operations.

- Clean Operation: Since they don’t use oil or fluids, pneumatic presses are clean and well-suited for environments where cleanliness is important (e.g., food production, electronics).

- Safety: Pneumatic systems tend to be safer than hydraulic ones, since hydraulic fluid leaks can be hazardous and air pressure can be more easily controlled.

Disadvantages

- Limited Force Control: Pneumatic presses offer less fine control over the applied force compared to hydraulic systems. This makes them less suited for precision applications requiring consistent force throughout the stroke.

- Less Power for Heavy-Duty Tasks: Pneumatic presses are better suited for lighter materials and operations, but are generally not as powerful as hydraulic presses for tasks requiring extreme force.

- Air Availability: Air presses and air-over-oil presses require a source of compressed air, which may be difficult in some environments.

Pneumatic and hydropneumatic presses are highly versatile tools for production and assembly, providing excellent speed, simplicity, and cost-effectiveness, especially for light- to medium-duty tasks in factory settings. If you are interested in an air press and wondering about additional features or optimal applications, we can help. Contact us today to learn more about pneumatic or hydropneumatic presses.

Interested in an Air-Powered Press for your next assembly project?

Provide details on the project applications and we can work up a custom quote for an air-powered press to deliver the required force with the efficiency of pneumatic power.