Air Over Oil Presses

Our high performance air over oil presses are the result of over 75 years of precision design and proven engineering. These 2.5 ton – 50 ton hydropneumatic presses run on a shop air supply and utilize minimal hydraulic oil, making them perfect hydraulic press alternatives with lower upfront investment cost, higher efficiency and minimal maintenance.

More Efficient

Our air over oil presses are powered by compressed air and run only when cycling. With no hydraulic pumps or electric motors as well, these presses are far more efficient than comparable hydraulic presses.

Quieter

Hydraulic presses produce constant noise and heat, whereas air over oil presses produce no heat and emit noise only during the press cycle, resulting in a much quieter, more comfortable working environment.

Safer

Hydraulic presses require high voltage electricity and large oil reservoirs, increasing risk to your team. With no high voltage energy, minimal and/or self-contained oil, and quieter operation, our air-over-oil presses are safer to operate.

Less Maintenance

Air over oil presses have fewer, less complex moving parts, requiring minimal maintenance to operate over their lifetime. They are also less expensive up front compared to hydraulic presses, providing you with a better, quicker ROI.

Air over oil presses, commonly referred to as hydropneumatic presses, are a great fit when you are looking for the reliability and efficiency of an air press but need the increased force typically offered in hydraulic presses. Our hydropneumatic air over oil presses use air as an energy efficient power source to intensify hydraulic oil and deliver up to 50 tons of force without the use of pumps, motors or high-voltage electricity. There are many benefits to air over oil presses as hydraulic press alternatives.

Some of the benefits of an air over oil press versus a full hydraulic press include:

- Reduced initial purchase cost

- Reduced long-term maintenance cost

- Reduced factory noise

- Improved safety due to the lack of high voltage power

- Ability to deliver force equivalent to many fully hydraulic factory presses

- Base models simply require a factory supplied airline to operate

Some of the benefits of an air over oil press versus a full hydraulic press include:

- Reduced initial purchase cost

- Reduced long-term maintenance cost

- Reduced factory noise

- Improved safety due to the lack of high voltage power

- Ability to deliver force equivalent to many fully hydraulic factory presses

- Base models simply require a factory supplied airline to operate

Our objective is to offer you the best solution to your assembly and forming needs. Please browse our air-over-oil press options below, or if you unsure which press will over the best performance and return on investment for your application, please feel free to reach out for our expert recommendation.

Our Hydropneumatic Air Over Oil Presses

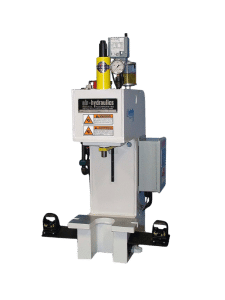

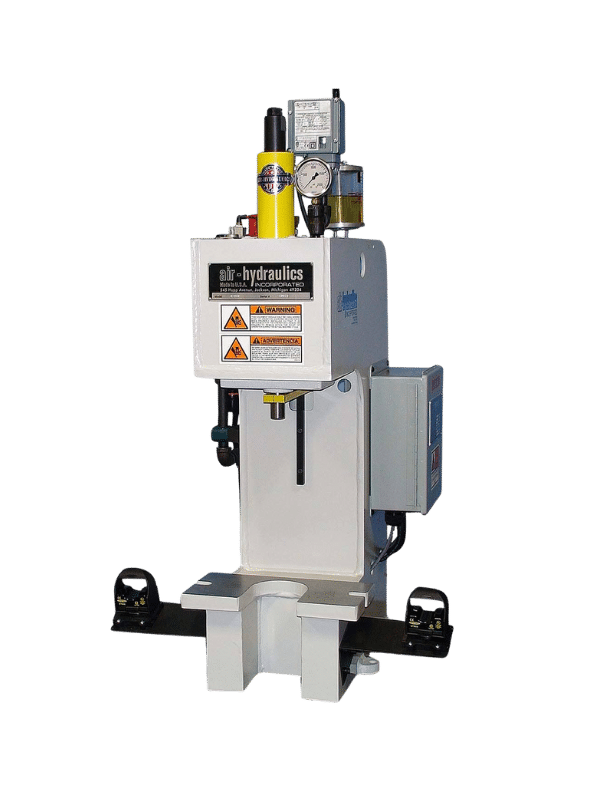

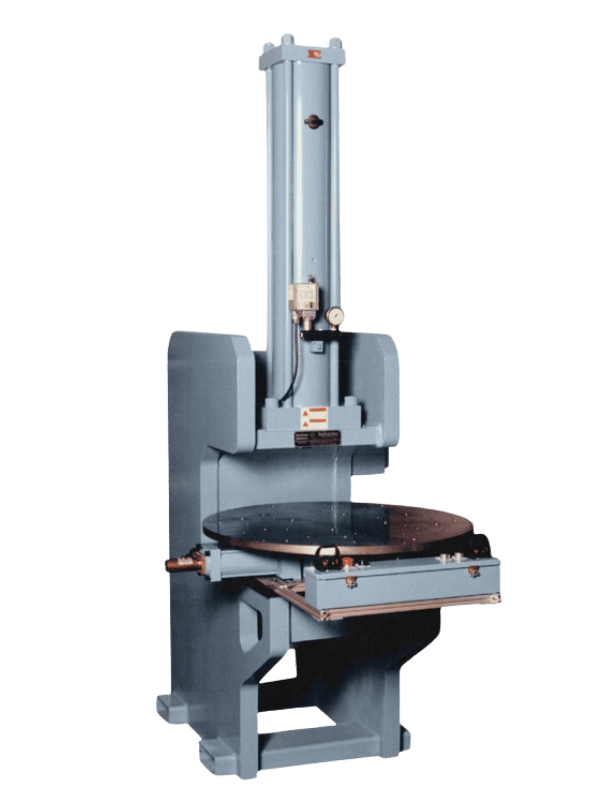

Air Hydraulics offers two lines and 10 different models of air over oil presses for industrial, manufacturing environments. The C-Series and AH-Series serve as superior alternatives to a hydraulic press for many assembly and production applications. Depending on your needs, we have options ranging from 2.5 tons of force up to 50 tons of force.

Applications: Bushing/Bearing Insertion, Stud Insertion, Swaging, Trimming, Marking or Character Stamping, Assembly, Notching, Joining, Forming, and Fastening

Models: 2.5 Tons, 5.5 Tons, 10 Tons, 15 Tons

- 2.5 to 15 Tons of Hydraulic Force Using Factory Air Supply

- More Cost Efficient Alternative to Full Hydraulic Presses

- Utilizes Shop Air as a Clean and More Energy Efficient Power Source

- Features a Full Length Hydraulic Controlled Power Stroke

- Quick Delivery on Certain Models

- Standard double ended rod with 2″ Adjustable Downstop (Mechanical Stroke Limiter)

- ANSI Compliant Two-Hand Non-Tie Down Control Actuators

- C-Frame Bench Top or Floor Model (optional 2-post or 4-post)

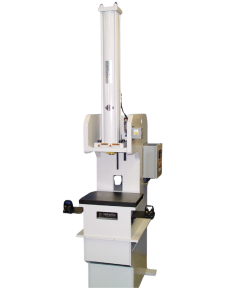

Applications: Riveting, Crimping, Punching, Swaging, Trimming, Marking or Character Stamping, Assembly, Notching, Joining, Forming, and Fastening

Models: 4 Tons, 9 Tons, 15 Tons, 20 Tons, 30 Tons, 50 Tons

- 4 Tons to 50 Tons of Hydraulic Force Using Factory Air Supply

- More Cost Efficient Alternative to Full Hydraulic Presses

- Utilizes Shop Air as a Clean and More Energy Efficient Power Source

- Features a Quick Approach Stroke with a Self-Contained .500” Hydraulic Intensified Power Stroke

- 6″ Overall Stroke (optional strokes available)

- ANSI Compliant Two-Hand Non-Tie Down Control Actuators

- C-Frame Bench Top or Floor Model (optional 2-post or 4-post)

SIG-Series Force and Distance Monitoring Air Over Oil Presses

Data Enabled C-Series Air Over Hydraulic Presses

Applications: Bushing/Bearing Insertion, Stud Insertion, Swaging, Trimming, Marking or Character Stamping, Assembly, Notching, Joining, Forming, and Fastening

Models: 2.5 Tons, 5.5 Tons, 10 Tons, 15 Tons

These data enabled Air-Over-Oil presses offer the same standard features as our signature C-Series Air-Hydraulic presses, with the added benefit of force and distance monitoring technology, which provides a boost to efficiency and quality control across applications.

Interested in learning more about how to select the right press for your application?

This free 30 page guide reviews 11 primary considerations when determining what press would be best for your business.

Custom Air Hydraulic Press Modifications

- Light Curtains & Guarding Packages

- PLC Control Options

- 2-Post and 4-Post Designs

- Load Cell & Distance Monitoring Packages [See Sig-Press]

- Custom Tooling and Fixture Packages

- 24vDC Control Circuits

- Emergency Stop Circuit

- Linear Position Transducer

- Selectable Modes of Operation

- Control Systems Designed for Future Expansion

- And more.

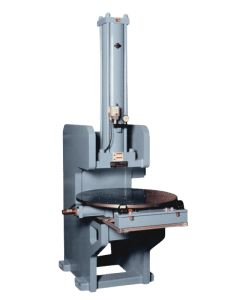

Custom Air-Over-Oil Press Examples

2.5 Ton Industrial Sheet Piercing Press

CASE ID: 12731

Looking for a Full Hydraulic Press?

We are known for our 75+ years of pneumatic and air over oil presses innovations. However, there is certainly a time and place for a full hydraulic press – if that’s what is needed for your application requirements, we’ve got you covered.

Get the Perfect Press for Your Application

Answer a couple questions about your application needs and we’ll send you a quote to help you solve it.