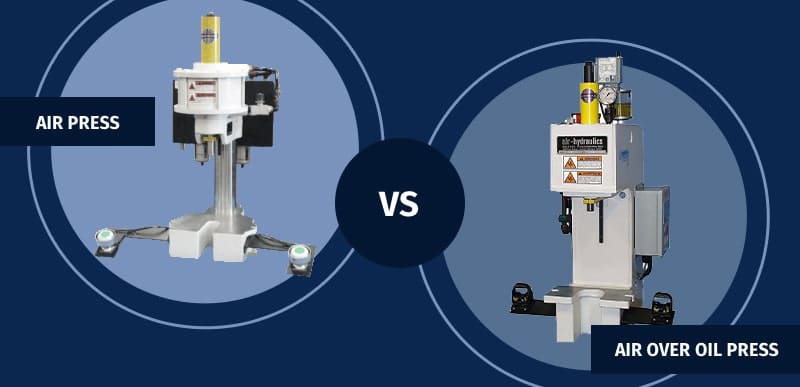

Among the many types of presses available, the air-over-oil press offers a unique combination of power and simplicity, as well as energy efficiency and lower costs. But, it can be difficult to determine when an air-over-oil press is ideal. Let’s take a look at what air-over-oil presses are, how they work, and when to choose an air-over-oil press for assembly applications.

What is an Air-Over-Oil Press?

An air-over-oil press, also called a hydropneumatic press, combines the simplicity of pneumatic systems with the precision and power of hydraulics. This combination allows manufacturers to achieve smooth, consistent force with a compact and relatively cost-effective system. Unlike standard pneumatic presses, which can sometimes lack the precision required for delicate assembly tasks, the hydraulic oil in an air-over-oil system provides stability and accuracy even at higher pressures.

Because of its hybrid nature, an air-over-oil press can also deliver higher force output than a purely pneumatic system while maintaining better energy efficiency and using less oil compared to fully hydraulic systems. This makes it a versatile solution for a range of factory assembly needs.

How Does an Air-Over-Oil Press Work?

The air-over-oil press operates in two main stages. First, compressed air is introduced into the system, pressurizing the hydraulic oil in the reservoir. This pressurized oil is then directed into the hydraulic cylinder, which moves the ram to perform the pressing action. This two-stage process allows for fine-tuned control over the force applied, making it possible to perform tasks that require substantial power. Additional systems, such as force and distance monitoring systems, can offer even more fine-tuning to detect defective parts during the pressing process, preventing costly field-failures.

Air-over-oil presses also allow for variable stroke speeds, which means the press can operate quickly for light tasks or it can slow down for jobs requiring greater accuracy. Additionally, many air-over-oil presses are equipped with features like pressure gauges, adjustable stroke lengths, and programmable controls, offering even more flexibility in assembly applications.

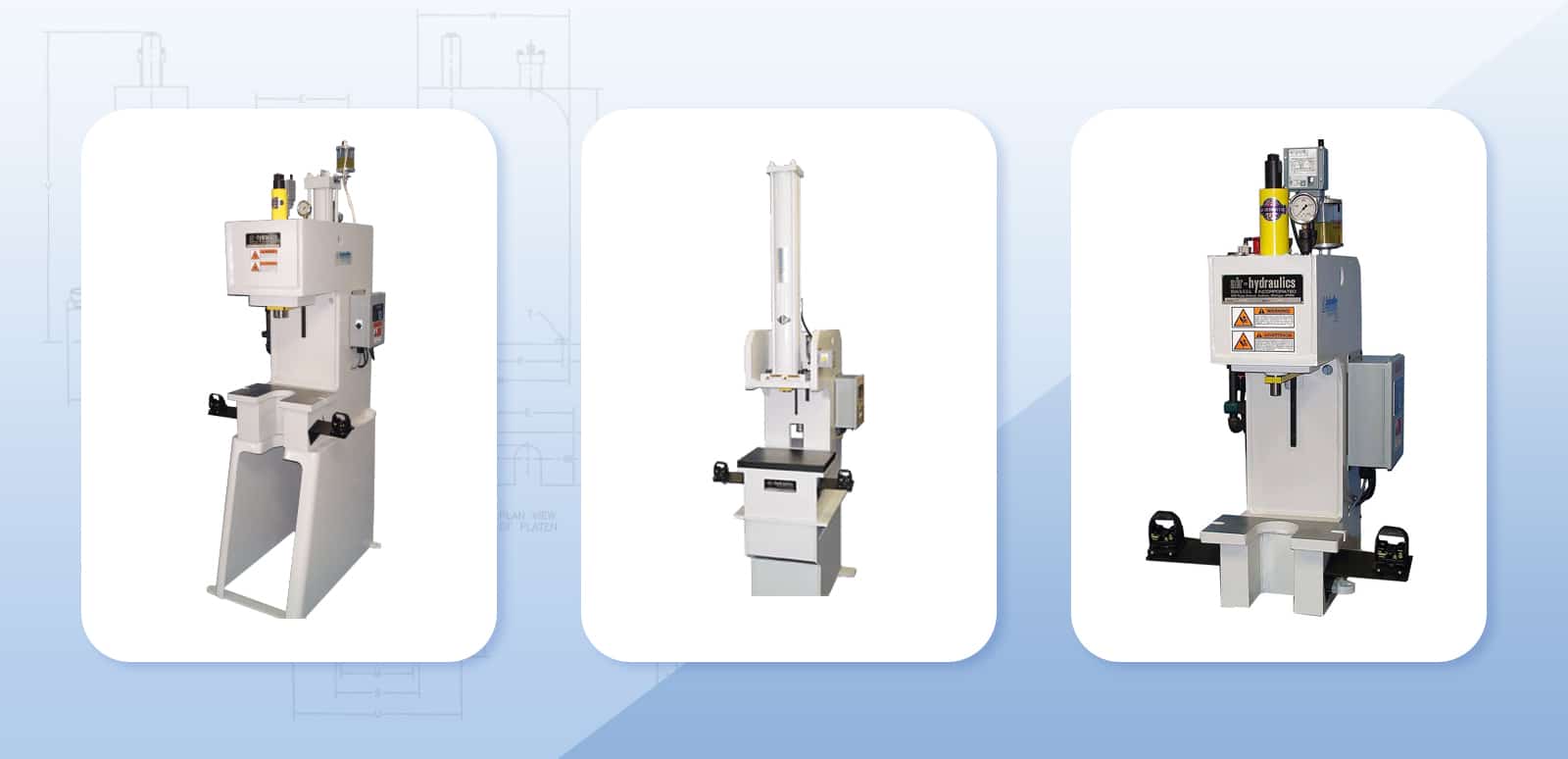

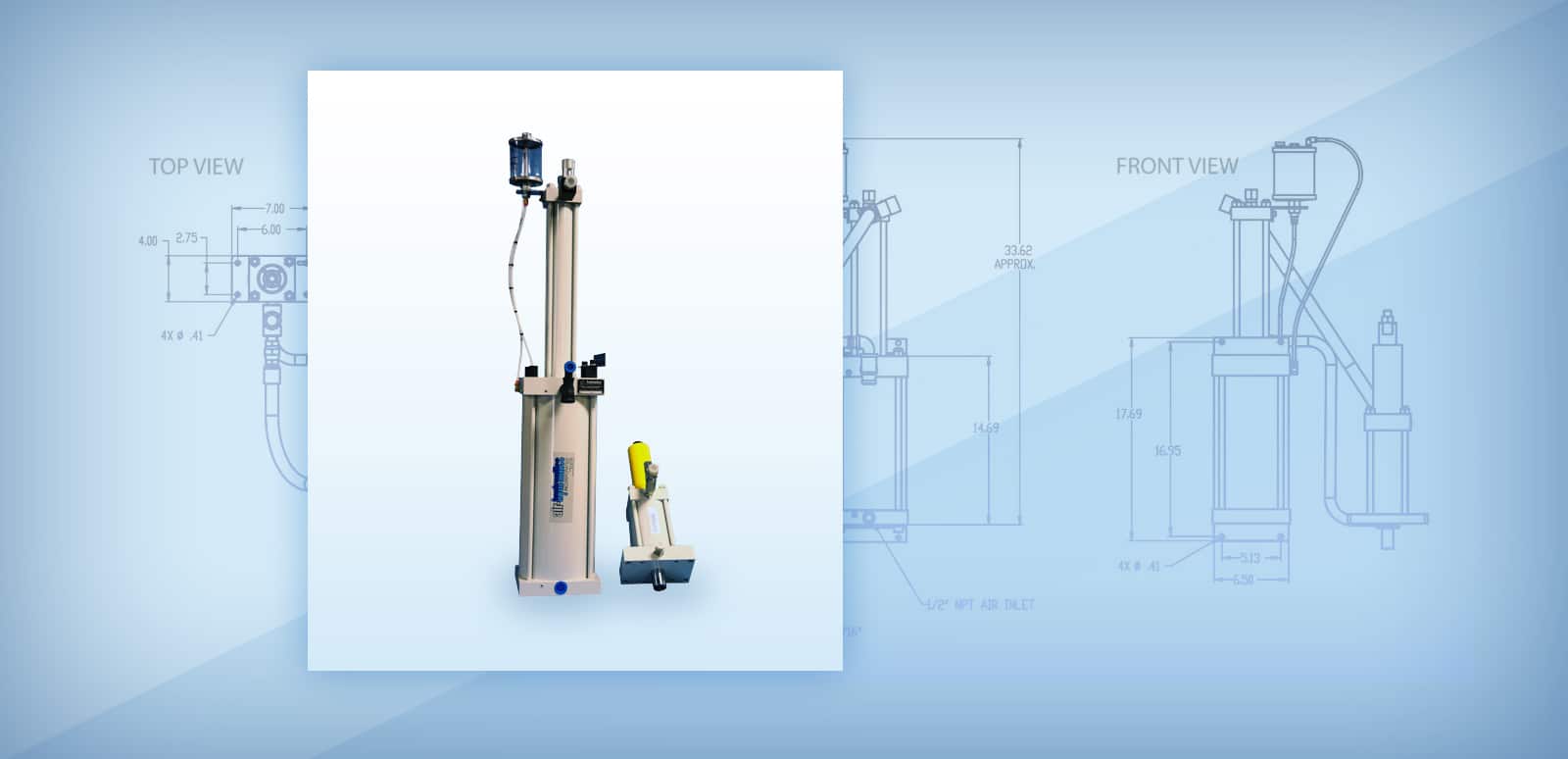

C-Series

Air Over Hydraulic Press

Applications: Bushing/Bearing Insertion, Stud Insertion, Swaging, Trimming, Marking or Character Stamping, Assembly, Notching, Joining, Forming, and Fastening

AH-Series

Hi/Lo Air Over Oil Press

Applications: Riveting, Crimping, Punching, Swaging, Trimming, Marking or Character Stamping, Assembly, Notching, Joining, Forming, and Fastening

When to Choose an Air-Over-Oil Press for Assembly Applications

Air-over-oil presses are versatile and well-suited for many assembly applications, particularly those that demand a balance of precision, controlled force, and repeatability. Below are some examples of tasks where these presses excel, along with specific scenarios to highlight their advantages.

Delicate Assembly Work

Air-over-oil presses are ideal for delicate assembly tasks where precision and control are critical. For example, when assembling sensitive electronic components, such as circuit boards or sensors, excessive force or sudden impacts can damage the fragile parts. The smooth and controlled motion of an air-over-oil press minimizes these risks, ensuring the parts are pressed or joined without damage. Similarly, these presses are often used in the assembly of medical devices, such as syringes or inhalers, where consistent results and a gentle touch are essential to ensure product safety and functionality.

Metal Stamping and Forming

For light to medium metal stamping or forming applications, air-over-oil presses provide the steady force needed to shape or cut metal components with precision. For instance, in the production of small brackets, connectors, or enclosures for electrical equipment, air-over-oil presses deliver clean cuts and uniform shapes. They are also commonly used for shallow metal embossing, where patterns or logos are stamped into sheets of metal without compromising the material’s structural integrity. The press’s ability to maintain consistent pressure ensures high-quality results, even for intricate designs.

Plastic Joining and Bonding

Air-over-oil presses are widely used for pressing plastic components together or bonding them during assembly. For example, in the automotive industry, they are employed to assemble plastic parts such as dashboard components or trim pieces, where precise alignment and consistent force are crucial to achieving a seamless fit.

Air-over-oil presses are also effective in ultrasonic welding applications, where the press applies controlled pressure while ultrasonic vibrations create a strong bond between plastic parts. The ability to finely adjust the press’s stroke length and force ensures that delicate plastic materials are not over-compressed or damaged during the process.

Press-Fit

Press-fit jobs, where one component is inserted into another with a precise fit, is another area where air-over-oil presses excel. A common example is inserting bearings, bushings, or dowel pins into machined parts, such as engine components or industrial machinery. The controlled motion of the press ensures that the parts align correctly and press into place without tilting, cracking, or excessive force.

In the aerospace industry, air-over-oil presses are often used for assembling precision components where even minor deviations could lead to performance issues or failures. The combination of accuracy and repeatability makes these presses an excellent choice for press-fit tasks.

Why Choose an Air-Over-Oil Press for These Jobs?

The air-over-oil press stands out for its ability to balance precision and power. Its advantages over purely pneumatic or hydraulic systems include:

- Energy Efficiency: Because compressed air drives the system, hydropneumatic presses use less energy compared to fully hydraulic systems, especially in applications where high force is only needed intermittently.

- Cost-Effectiveness: These presses are typically less expensive to purchase and maintain than full hydraulic systems, making them an excellent choice for factories seeking high performance without breaking the budget.

- Compact Design: Air-over-oil presses are often more compact than equivalent hydraulic presses, allowing them to fit into tighter spaces on the factory floor.

- Enhanced Precision: The use of hydraulic oil ensures consistent, smooth motion, even during high-force applications, making these presses ideal for jobs that require tight tolerances.

- Grows With You: With a wide range of force output and a number of features increasing their versatility, air-over-oil presses will be able to grow with your factory. These presses can perform different tasks and work with different materials as you expand your jobs and capabilities.

Choosing the right press for your assembly application is critical to ensuring efficiency, precision, and cost savings. Air-over-oil presses provide a great balance of power and precision, making them ideal for a wide range of light to medium assembly tasks. Their versatility, energy efficiency, and compact design make them a valuable addition to any production line. If your looking for an air-over-oil press for assembly applications, we can help. Contact us today to learn more about highly efficient, cost-effective air-over-oil presses.

.

.

The hi/lo hydropneumatic cylinder uses compressed air and hydraulic oil to multiply the force behind the press. In general, the cylinder goes through these steps:

The hi/lo hydropneumatic cylinder uses compressed air and hydraulic oil to multiply the force behind the press. In general, the cylinder goes through these steps:

C-Frame Hydraulic Press

C-Frame Hydraulic Press A hydropneumatic press is a great alternative to a purely hydraulic press for manufacturing and assembly. The Air Hydraulics line of

A hydropneumatic press is a great alternative to a purely hydraulic press for manufacturing and assembly. The Air Hydraulics line of

Pneumatic systems are known for their speed and responsiveness. Air-oil boosters maintain this characteristic, providing rapid actuation and quick cycling of the system.

Pneumatic systems are known for their speed and responsiveness. Air-oil boosters maintain this characteristic, providing rapid actuation and quick cycling of the system.