Choosing the best benchtop pneumatic press is essential for businesses looking to enhance efficiency, precision, and reliability in their manufacturing or assembly operations. These compact, yet powerful tools are designed to deliver consistent force while minimizing energy use, making them a practical choice for a wide range of applications. Let’s take a closer look at benchtop pneumatic presses, including what a pneumatic press is in general, how it differs from other industrial presses, and the key features to consider when selecting the best benchtop pneumatic press for your needs.

What is a Pneumatic Press?

First, what is a pneumatic press, and how does it differ from other types of benchtop presses? Understanding the differences can help ensure that a pneumatic press is the right fit for your job, and determine which type of benchtop pneumatic press will be ideal.

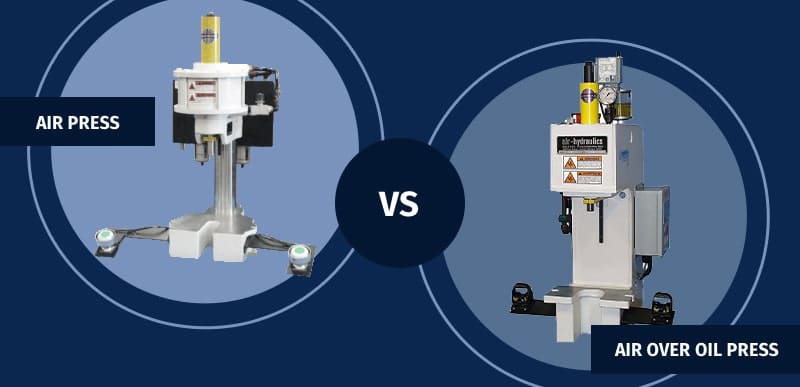

A pneumatic press, also called an air press, is an industrial machine that uses compressed air to generate force for tasks such as pressing, stamping, crimping, or forming materials. Unlike hydraulic presses, which rely on compressed liquid, or mechanical presses, which use mechanical energy, pneumatic presses operate using air pressure supplied by a compressor or a shop air system. This design makes pneumatic presses simpler to operate and maintain while offering a cleaner, quieter alternative to hydraulic systems. Pneumatic presses also offer higher accuracy, improved repeatability, and virtually no operator strain compared to manual or arbor press options.

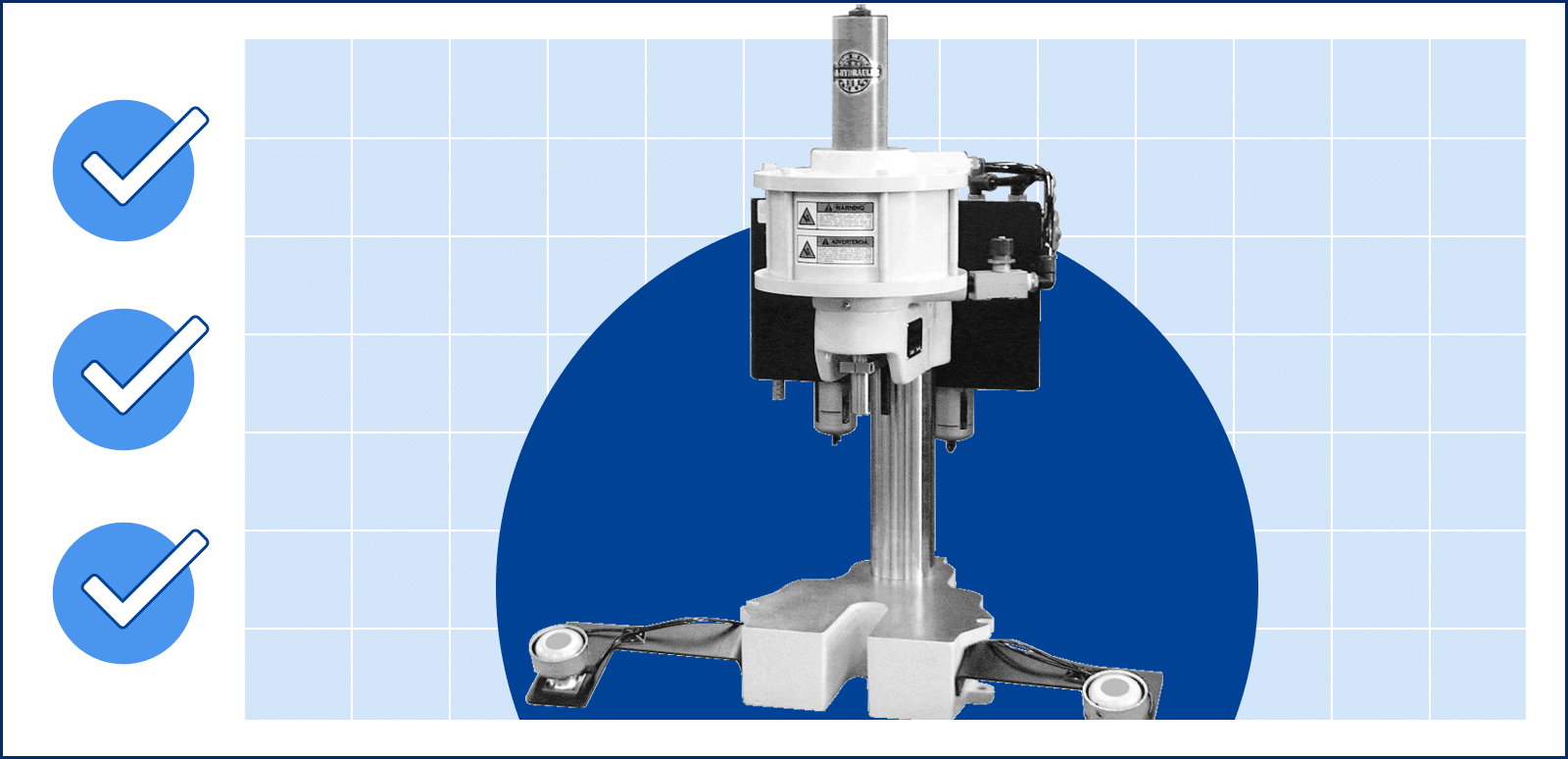

The AP-Series Air Press features a compact, robust frame that has minimal deflection for those small precise application projects. It also does not require lubricated air, which makes it a great choice for clean room environments.

Whereas, our A-Series Adjustable Air Press offers flexibility by featuring an easy full head cylinder adjustment design, which is ideal for die-set applications and for changeover between applications.

How Are Pneumatic Presses Different?

Pneumatic presses, hydraulic presses, mechanical presses, and hydropneumatic presses share some similarities, but there are also important differences. The primary difference between pneumatic presses and other industrial presses lies in their power source and operational efficiency.

Pneumatic presses utilize compressed air pressure, making them lighter, faster, and more energy-efficient than hydraulic presses, which require complex fluid systems. Hydraulic systems also require more complex maintenance to prevent issues and ensure they’re working properly, while the maintenance for pneumatic systems is typically much simpler. Pneumatic systems are also easier to install, as they often connect directly to a standard shop air supply. Unlike mechanical presses, which deliver force through flywheels and cranks, pneumatic presses provide more precise control over force application, reduce operator strain compared to manually operated presses and ensure repeatability.

Applications for Pneumatic Presses

Though many pneumatic presses can generate several tons of force, most provide a moderate level of force. Common uses include:

- Assembly Operations: Press-fitting, staking, and riveting components.

- Manufacturing Processes: Punching, embossing, and light metalworking.

- Electronics Assembly: Handling delicate tasks like pressing sensitive components.

- Clamping Operations: Press and hold operations where pressure needs to be maintained to clamp the part or assembly so secondary operations can be performed (eg. leak/pressure testing)

- Plastic Forming: Shaping and sealing plastic parts.

Their versatility and precision make pneumatic presses a popular choice in industries such as electronics, automotive, and packaging.

Advantages of Pneumatic Presses

Pneumatic presses offer several advantages that make them a go-to solution for many businesses:

- Energy Efficiency: By utilizing shop air, pneumatic presses require less energy compared to hydraulic presses, which require energy-intensive pumps and fluid systems. Air presses also only consume shop air when in use, which cuts down on overall energy use altogether.

- Compact Design: Their simple construction often results in a smaller footprint, making them perfect for benchtop applications.

- Ease of Maintenance: Pneumatic systems are easier to maintain than hydraulic systems, which involve fluids and seals prone to leaks.

- Precision and Control: The ability to adjust air pressure and cylinder rod speed allows for fine control over the force applied, enhancing accuracy for delicate or small-scale operations. Double Rod End Cylinders also provide a mechanical method to prevent over-travel of the cylinder rod.

What to Look for in a Benchtop Pneumatic Press

A benchtop pneumatic press can be a great addition to your workplace. However, it can be difficult to get the right model, since there are many different types and customizations to choose from. When selecting the best benchtop pneumatic press for your needs, consider the following factors:

- Force Capacity

It’s important to consider how much force the press can generate, as well as how much force your job requires. Benchtop pneumatic presses can provide hundreds or thousands of pounds of force. However, it can be difficult to generate multiple tons of force. Matching the force capacity to the requirements of your materials and applications will ensure that you’re not paying more for energy than you need to, while also ensuring that your press can easily finish the job. It’s recommended to size your pneumatic air press so that your pressing application requires no more than 75% of the press’ force capacity. - Dimensions and Footprint

Ensure the press fits comfortably on your benchtop and leaves enough space for operators to work around it. Compact presses are ideal for smaller workstations, but larger models may offer additional capabilities for more demanding tasks. - Adjustability

Look for presses that can be easily adjusted to accommodate different workpieces. Features such as adjustable stroke length, die height, and pressure settings are crucial for versatility and precision. - Durability and Build Quality

Consider your working conditions, and the requirements for your press’s durability. A press with a long lifetime will be made from high-quality materials, and it will be able to withstand repetitive use and heavy loads. Steel frames and components are ideal for long-term reliability. It might also be important to consider surrounding conditions, such as humidity, dust, or moisture. - Ease of Integration

If the press will be part of an automated production line, ensure it can integrate with your existing systems. Pneumatic presses compatible with PLCs (programmable logic controllers) or other automation tools, like sensors and monitoring devices, can significantly enhance productivity. - Safety Features

Safety mechanisms such as two-handed operation, emergency stop buttons, and guards can help protect workers and enable more efficient operation. Other safety features, like light curtains or interlocking doors can also help make your pneumatic press safer and easier to use, depending on your application.

Additional Considerations

- Noise Levels: While pneumatic presses are quieter than hydraulic ones, consider models designed to minimize operational noise further.

- Cost and Value: Compare prices across models, but prioritize value over cost. A higher-priced press with better durability and features may save you money in the long run.

- Manufacturer Support: Choose a press from a reputable manufacturer that offers warranties, training, and after-sales support.

Benchtop pneumatic presses offer a powerful and compact solution for many manufacturing and assembly operations, excelling in energy efficiency, precision, and versatility. By understanding their unique advantages and carefully evaluating factors like force capacity, footprint, and adjustability, you can find the best benchtop pneumatic press to suit your needs. If you have questions about benchtop pneumatic presses, or other types of presses for manufacturing and assembly, we can help. Contact us today to get your questions answered.