Light Curtains and Guarding

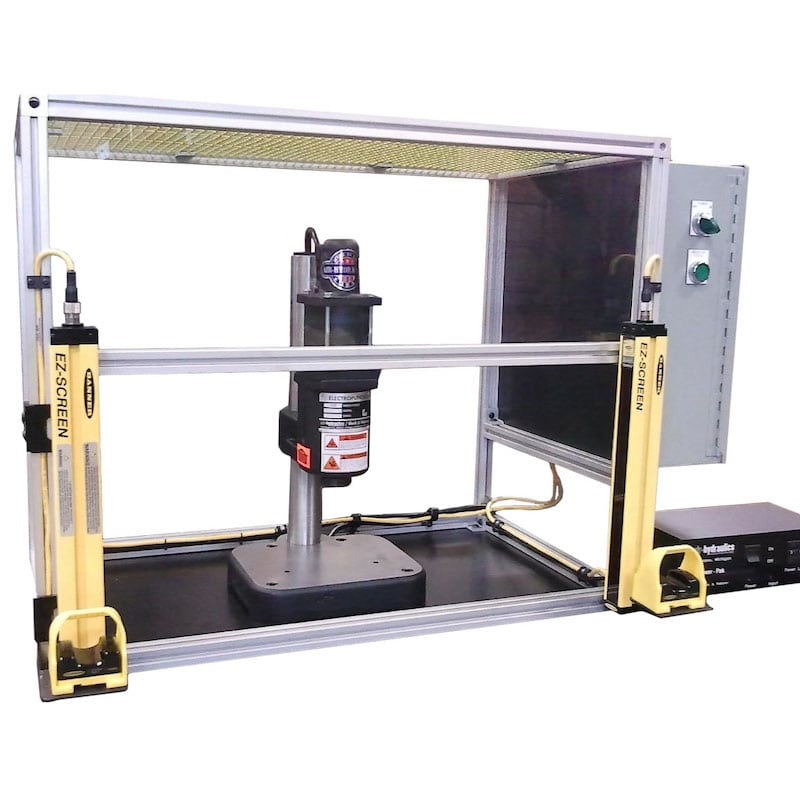

Press barrier guarding and light curtains offer additional safety protection for operators and others near the press working area. Guarding enclosures can cover a specific area, partially surround the press or fully enclose the press in combination with interlocking access doors. Light curtains on the other hand, give workers the power to move around the press and access the working area comfortably as needed. This versatile safety feature forms an invisible barrier of light beams in a set area around the press or through an entry or exit area that if disrupted, automatically stops or retracts the press, depending on the condition. Take a look at a few examples of our presses equipped with light curtains and/or other press guarding features.

- All

- Air Presses

- Air-over-Oil Presses

- Force and Distance Monitoring

- Hydraulic Presses

- Impact Hammers

- Turnkey & Automation Systems

Let’s Work Together