Servo electric presses have revolutionized the manufacturing world through exceptional control, precision, and efficiency. Many of the products we rely on every day are only possible through the use of servo electric presses. These presses use servo motors to power the pressing mechanism, allowing for programmable motion and force, which can be adjusted in real-time based on immediate feedback. Let’s take a closer look at how these presses work and the key advantages of a servo electric press.

How Does a Servo Electric Press Work?

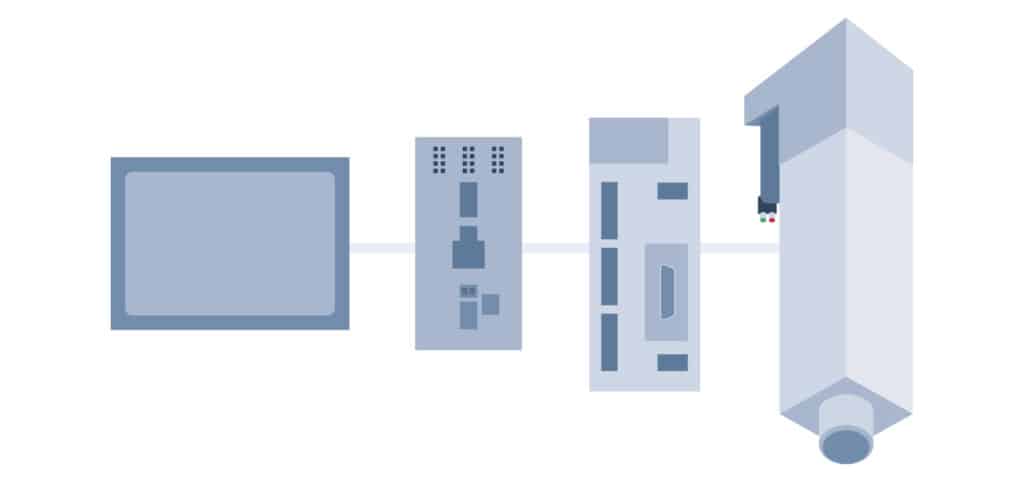

Understanding how a servo electric press works can help in understanding the key advantages it offers. A servo electric press uses an electric servo motor to power the press ram. While other types of presses use fluid pressure, air pressure, or mechanical devices to create force, servo electric presses use the motor to deliver precise control over motion, speed, and pressure.

The system relies on a feedback loop between sensors and the motor to allow for real-time adjustments. Operators can program different motion profiles, allowing them to increase or decrease speed or force at various stages of the cycle. This level of control is essential for complex manufacturing tasks that require varying pressures or precise movements to form, bend, or shape materials.

In addition, the motor operates only when it’s needed, making it highly energy-efficient. When the press is idle, it consumes little to no energy, reducing both operational costs and the environmental footprint of the manufacturing process.

Interested in Electric Servo Motor Presses?

Contact us to learn about your options >

Servo Electric Presses vs Standard Industrial Presses

Compared to standard industrial presses like hydraulic or pneumatic presses, servo electric presses offer a few important advantages.

- Customizable Motion: Traditional presses are typically limited to a fixed cycle of motion, which can be inefficient when handling complex tasks. Servo electric presses, on the other hand, can adjust their speed and force mid-cycle, offering a tailored approach to each material or task.

- Consistent Accuracy: Mechanical presses may lose precision over time due to wear and tear. Servo electric presses rely on a digital control system, so they maintain high accuracy and consistency over thousands of cycles.

- Cleaner Operation: Hydraulic presses require oil or other fluids, which can lead to leaks or spills, resulting in a messier work environment and higher maintenance needs. Servo electric presses, with their motor-driven system, avoid these issues altogether.

- Energy Savings: Hydraulic and mechanical presses generally consume energy even when they’re idle, especially if the hydraulic system remains under pressure. Servo presses only use energy when the press is operating, significantly reducing power consumption.

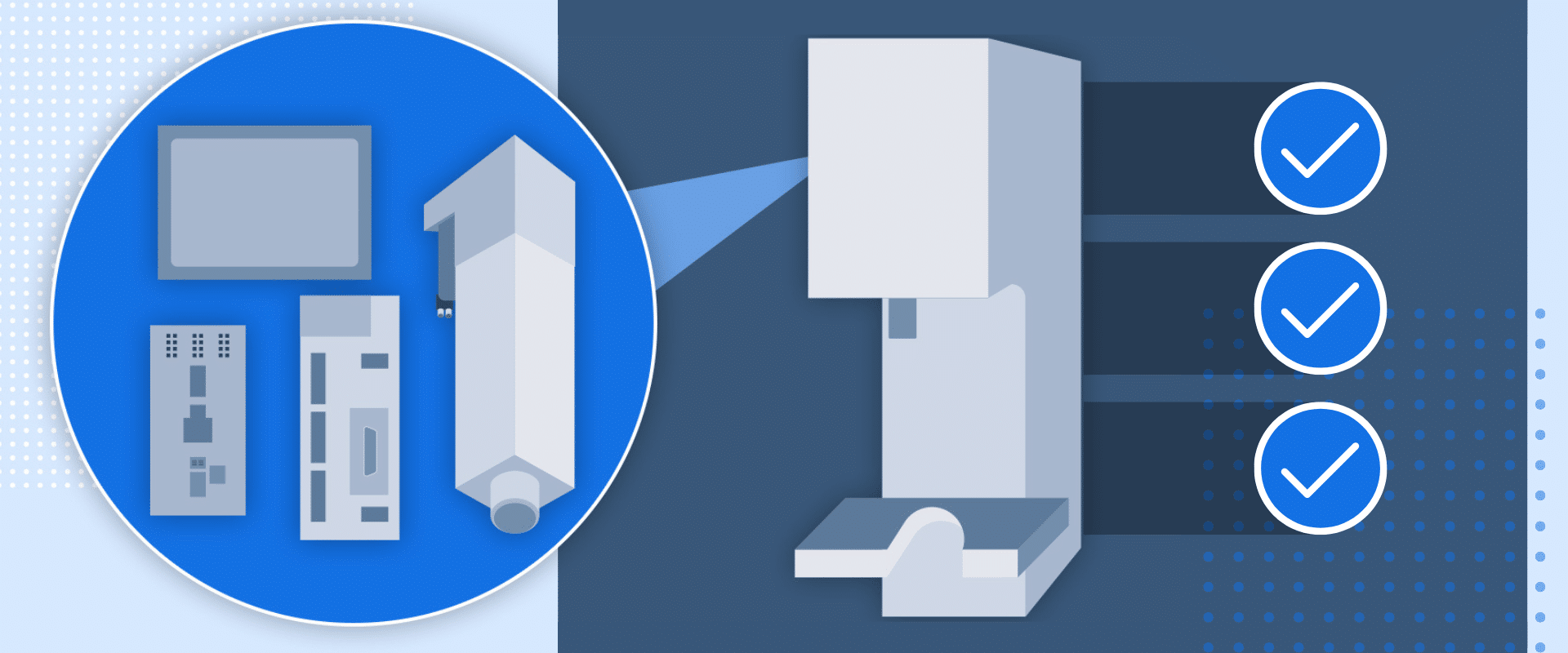

Advantages of a Servo Electric Press

With these differences in mind, let’s take a look at some advantages of a servo electric press. Though this type of press isn’t an optimal fit for all tasks and applications, it offers several advantages which can be ideal for complex tasks and high-volume production.

1. Enhanced Precision and Control

One of the greatest advantages of a servo electric press is the superior control over the press cycle. Operators can fine-tune the exact force, speed, and position required for each application. This ensures that the press delivers consistent results, part after part, even when producing high volumes.

3. Energy Efficiency

Servo electric presses are among the most energy-efficient presses available. They use power only when needed, drastically cutting energy consumption compared to hydraulic presses, which need to maintain constant fluid pressure. Over time, this can lead to significant cost savings in energy bills, making them a more environmentally sustainable option.

4. Versatility in Applications

Servo presses can be adapted to perform a wide range of tasks, from heavy-duty metal forming to more delicate applications such as assembly and joining. Their ability to operate with different levels of force and adjust speed mid-cycle makes them ideal for materials of varying thickness and properties, enabling manufacturers to streamline multiple processes with a single machine.

5. Lower Maintenance Requirements

Servo electric presses generally require less maintenance compared to hydraulic and mechanical presses. With fewer parts susceptible to wear, and no reliance on hydraulic fluids, the risk of breakdowns is minimized. This not only reduces downtime but also lowers repair and replacement costs, improving long-term operational efficiency.

6. Quieter and Cleaner Operation

Hydraulic presses are notorious for their noise and fluid-based systems, which can result in spills or leaks. Servo electric presses are less noisy due to the nature of the electric motor, creating a more comfortable work environment. They also eliminate the risk of oil spills and contamination, leading to a cleaner and safer production space.

7. Real-Time Monitoring and Feedback

Servo electric presses are equipped with advanced sensors and feedback systems that allow operators to monitor the pressing process in real-time. This immediate feedback means that any adjustments can be made on the fly, helping to detect defects early and ensure consistent quality throughout the production run.

8. Programmable Flexibility

Manufacturers can pre-program different press profiles for various tasks, allowing for seamless transitions between different parts or processes. This makes servo electric presses ideal for production environments where multiple products are being produced on the same line, reducing changeover times and enhancing overall productivity.

9. Long-Term Cost Savings

While servo electric presses may have a higher initial investment compared to other press types with similar functionality, their long-term benefits—including reduced energy consumption, lower maintenance costs, and increased productivity—make them a cost-effective choice in the long run.

Servo electric presses are an invaluable tool in modern manufacturing, offering a unique combination of precision, flexibility, and energy efficiency. By enabling real-time control and feedback, reducing operational costs, and providing cleaner and less noisy operation, these presses can provide factories and businesses many advantages with the right application.