Case ID: 0990

Application Details: Design and manufacture a two-hand operator controlled press with an indexing table machine to accept customer designed custom tooling and pressing fixtures

| Requirement: |

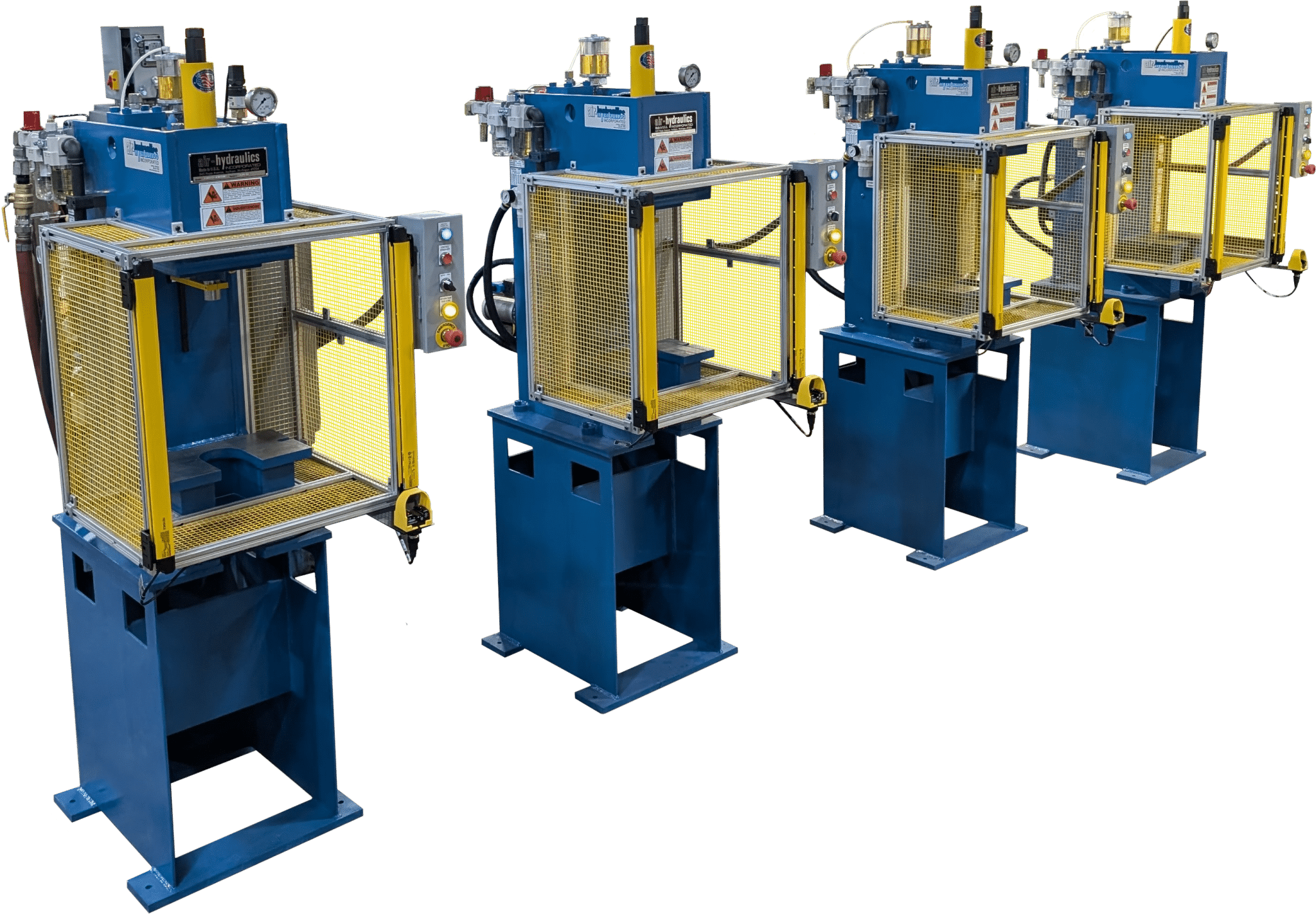

Design a Semi-Automatic / Operator Initiated Machine with Up to 50 Tons of Force to Stake Bracket Assemblies. Customer To Supply Part Fixtures and Staking Tool |

| Solution: |

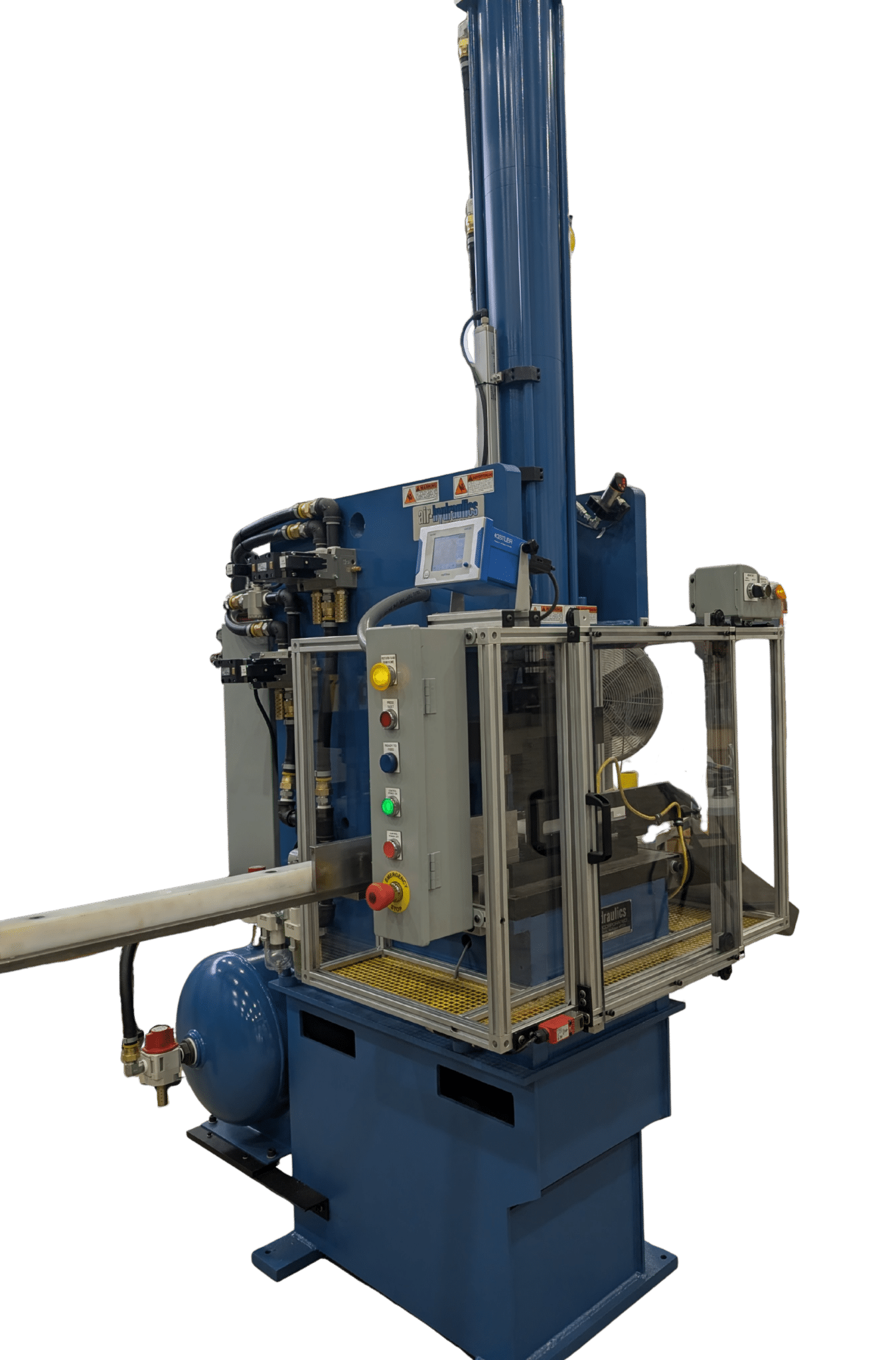

Custom Designed Two-Hand Controlled Model AH50L-CF Hydropneumatic Press with 1581-8 Station Rotary Indexing Table and a 30” Diameter Sub-Plate Machine to Accept Customer Supplied Fixtures |

This semi-automatic indexing machine is a combination of our 50 Ton AH-Series Hydro-Pneumatic press and our 15” Pneumatic Indexing Table, with two-hand control initiation. This package allows the operator to be in control of loading and unloading the part assemblies, while increasing throughput by relying on the indexing table to consistently align the part assemblies to be staked. This leads to an increase in production speed and product quality, while still allowing the operator to visually inspect the assembly process.